Any Length According to Customer Dimension Drawing

Steel/Aluminum/Carbon Fiber

Depend on Design

10-12 Days for Normal Order, Hurry Order is Negotiable

Wooden Box / Paper Box / Paper tube / Bubble Film

By Sea / By Air / By Train / By Fedex or other Express way

ISO9000/CE/ROHS/Certificate of Origin

Technical Video Support

T/T/Credit Card/Paypal.....

| Availability: | |

|---|---|

| Quantity: | |

| PDF Export | |

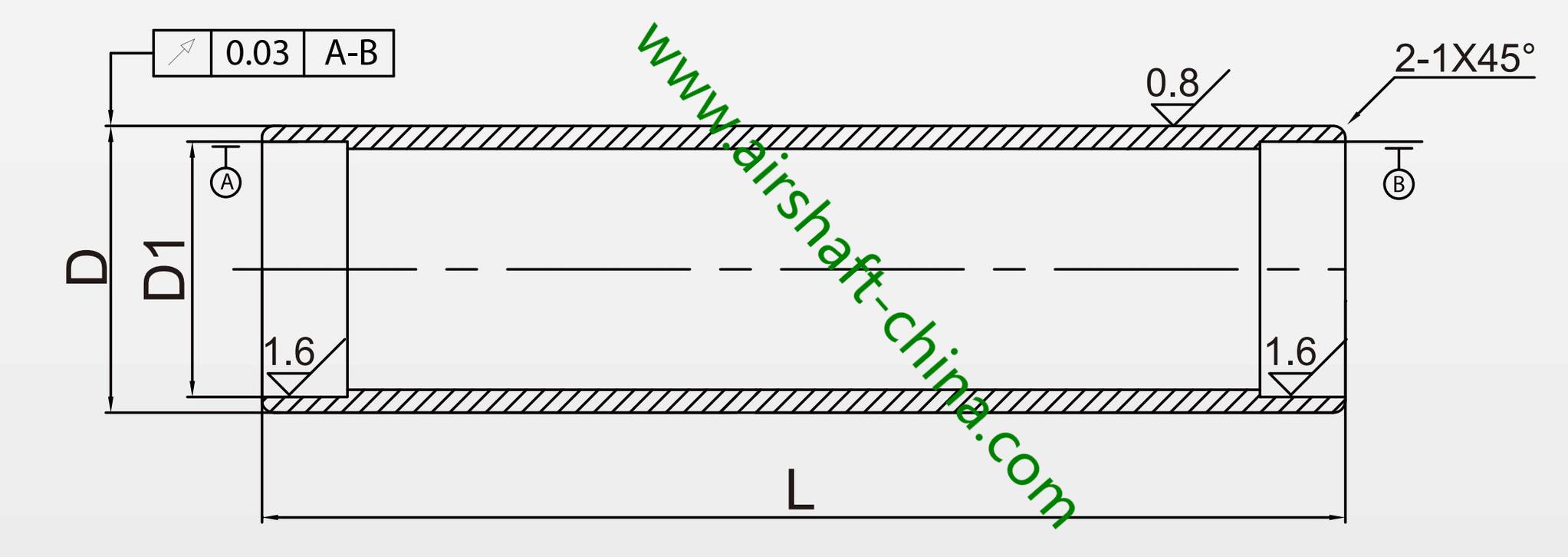

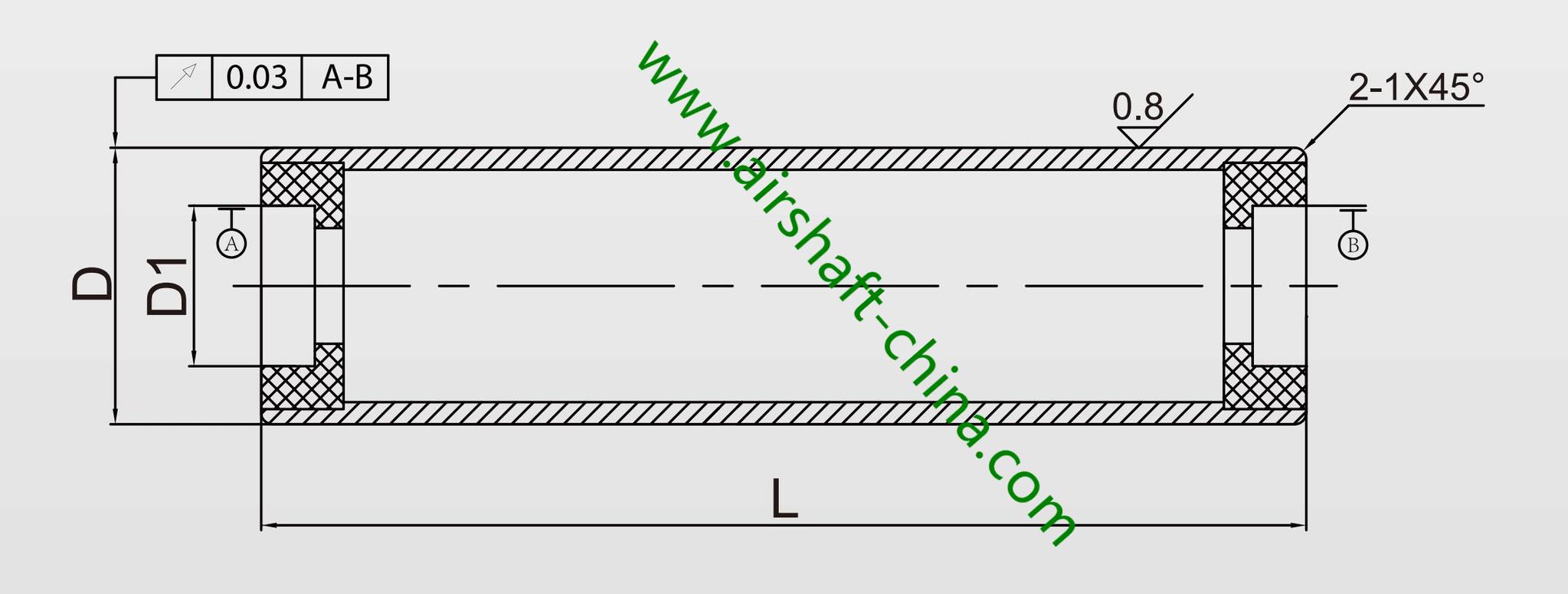

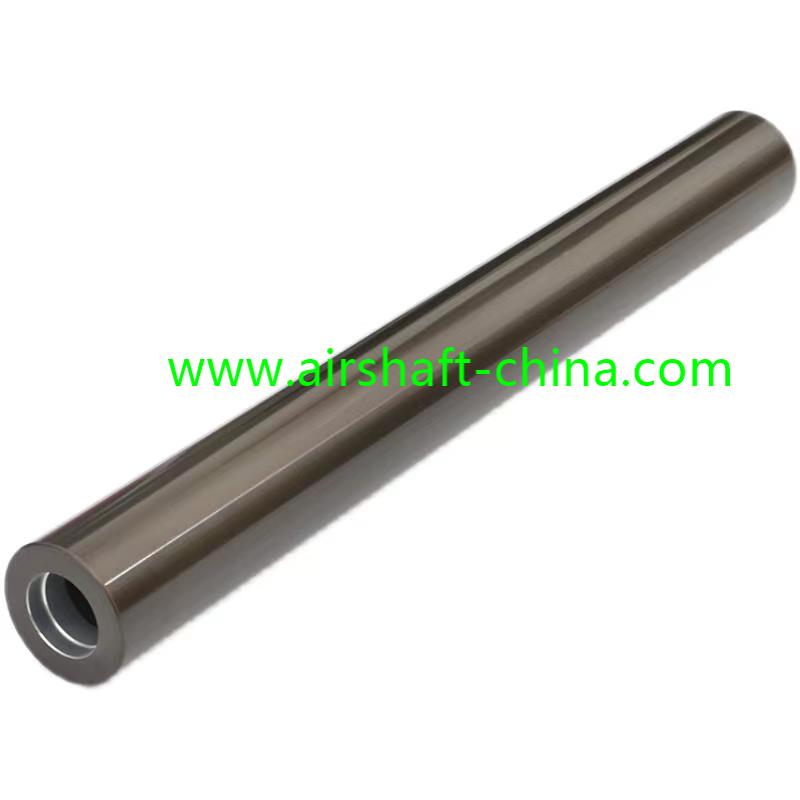

The minimum concentricity of this Aluminum Roller can reach 0.02mm.

The surface treatment of Aluminum Guide Roller can reach RA 0.8, Mirror effect could reach RA 0.4.

Aluminum Roller is widely used in every industry, especially Printing, Packing, Plastic, Paper, Glass, Textile..........

The aluminum roller serves various functions depending on the specific context or industry. Here are a few common applications and uses of aluminum rollers:

1. Printing and Graphics: In the printing industry, aluminum rollers are used in printing presses. They help transfer ink from the printing plate to the paper or other printing substrates. The smooth surface of the roller ensures even ink distribution and helps create high-quality prints.

2. Conveying and Processing: Aluminum rollers are often used in conveyor systems for material handling and processing. They can be employed in industries such as manufacturing, packaging, and food processing to transport goods or materials along a production line. The lightweight nature of aluminum makes it suitable for applications where reduced weight and ease of movement are desired.

3. Laminating and Coating: Aluminum rollers find use in laminating and coating processes. For example, in the production of laminated films, the roller applies pressure to bond layers together and ensure uniform adhesion. Similarly, in coating applications, such as applying adhesives or coatings to surfaces, the roller assists in spreading and smoothing the coating material.

4. Industrial Applications: Aluminum rollers are utilized in various industrial processes, such as calendering (smoothing and flattening materials like paper or plastic), embossing (creating textures or patterns on surfaces), and metalworking (rolling sheets or bars). They can also be used in machinery for tasks like guiding, tensioning, or supporting materials during manufacturing operations.

5. Wrinkle Removal and Surface Treatment: In certain applications, aluminum rollers are employed to remove wrinkles or imperfections from materials. For instance, in the textile industry, fabric is passed through heated aluminum rollers to smoothen the surface and remove creases. Additionally, aluminum rollers can be used for other surface treatments, such as burnishing or polishing.

It's important to note that the specific design, size, and surface properties of aluminum rollers can vary based on the intended application.

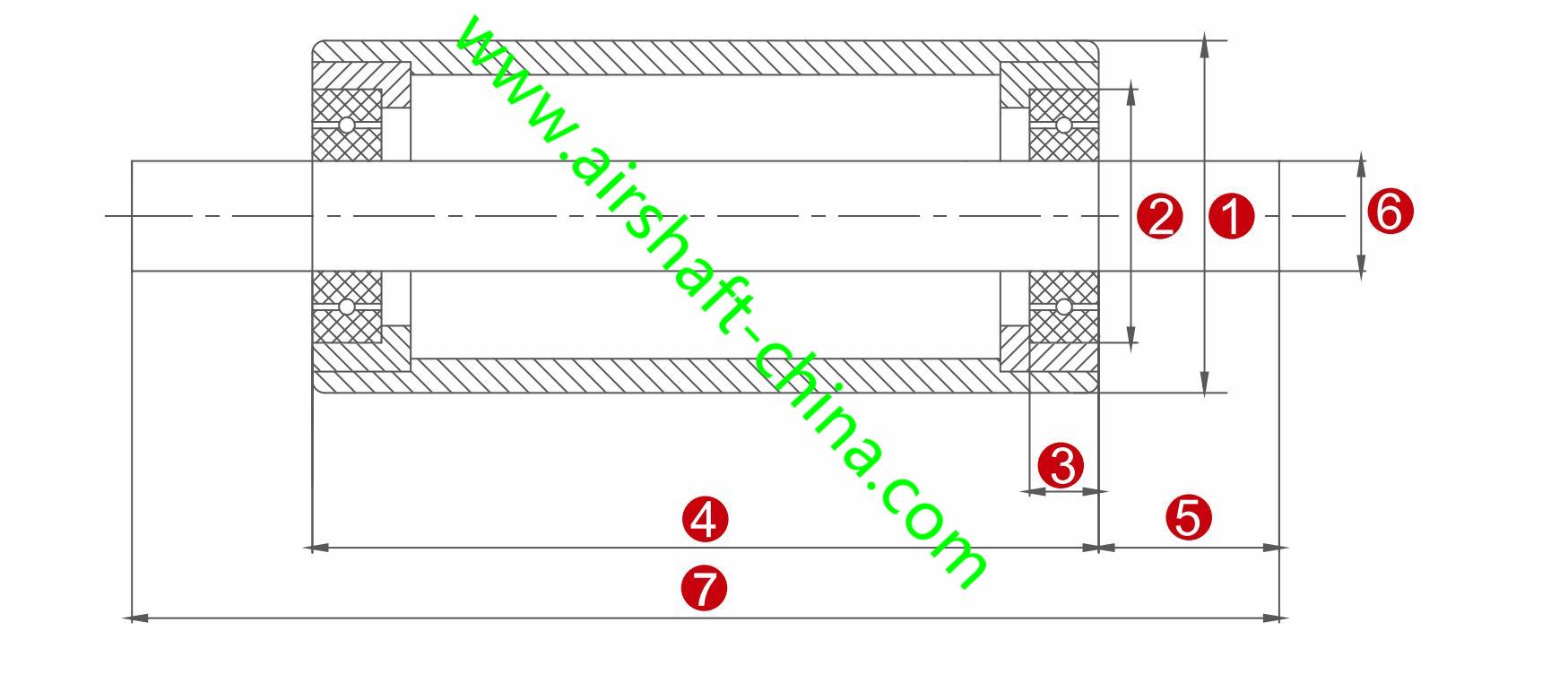

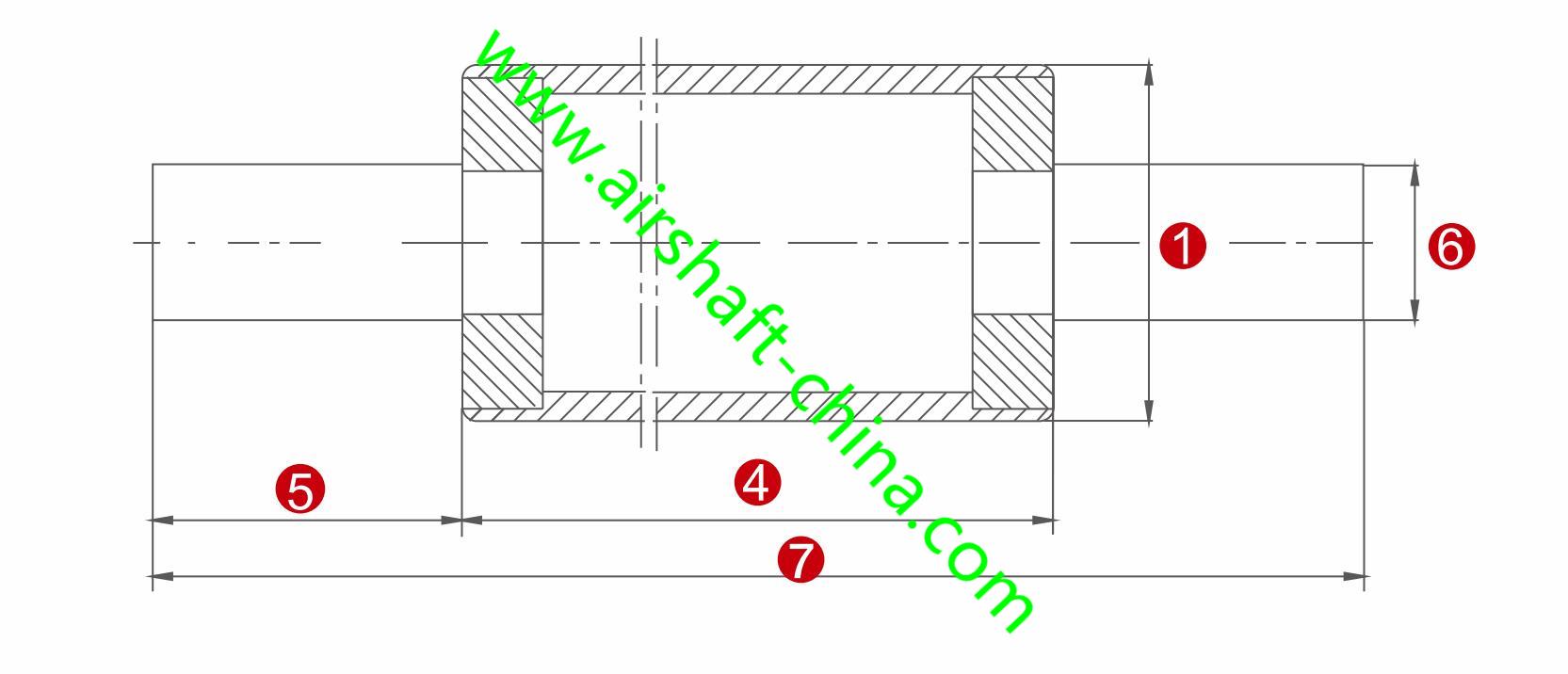

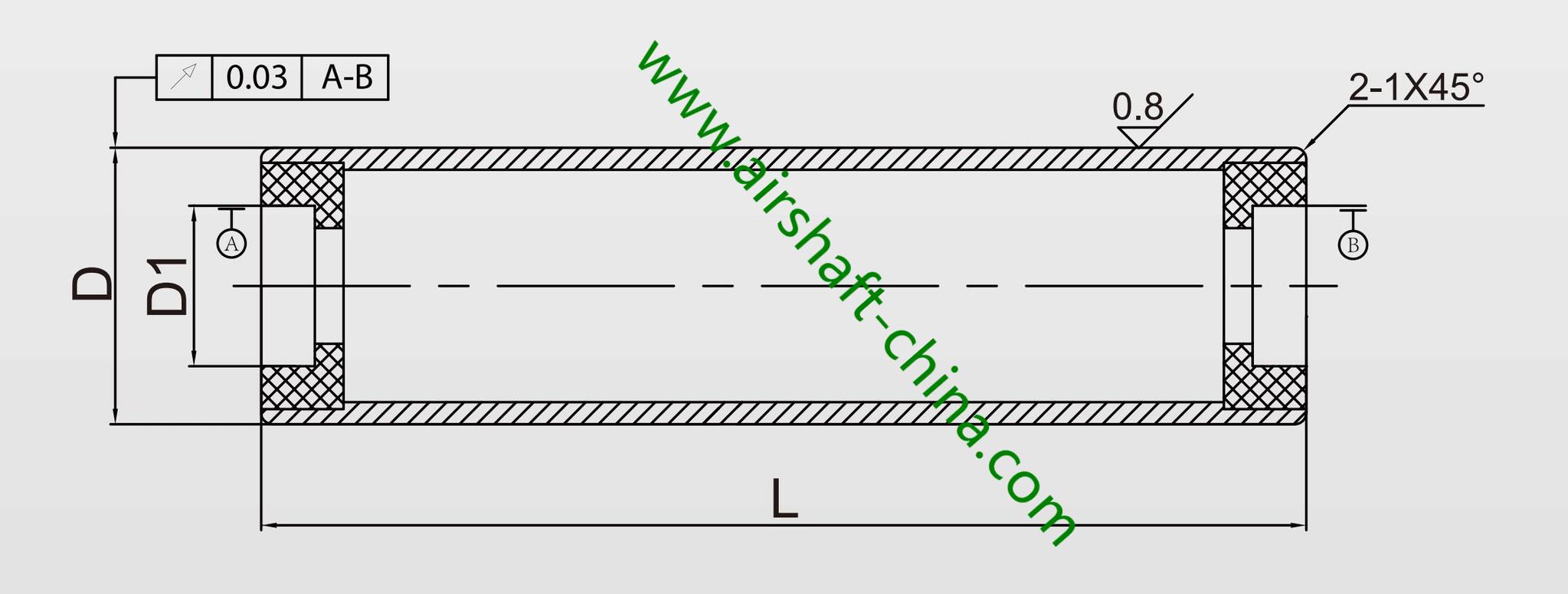

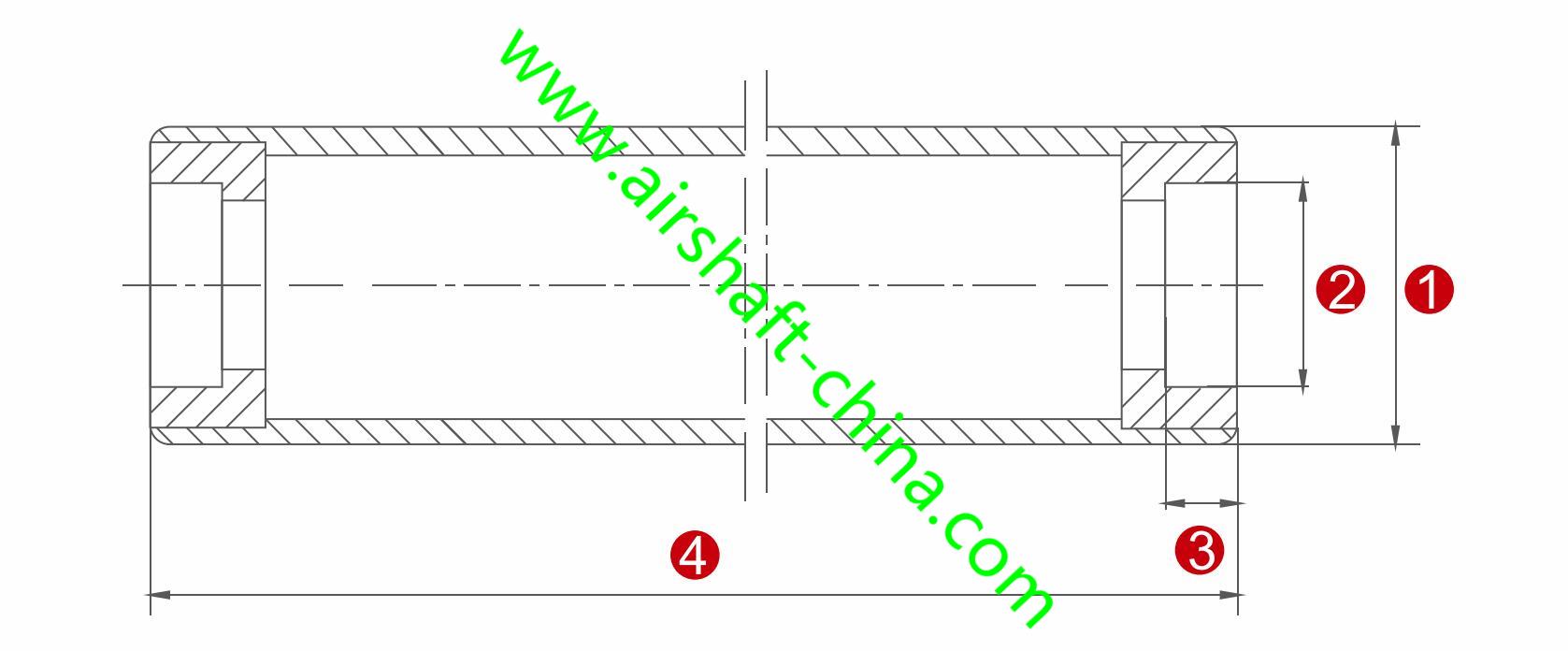

(1) ----Flat Tube type Aluminum Guide Roller

(2) ----No shaft type Aluminum Guide Roller

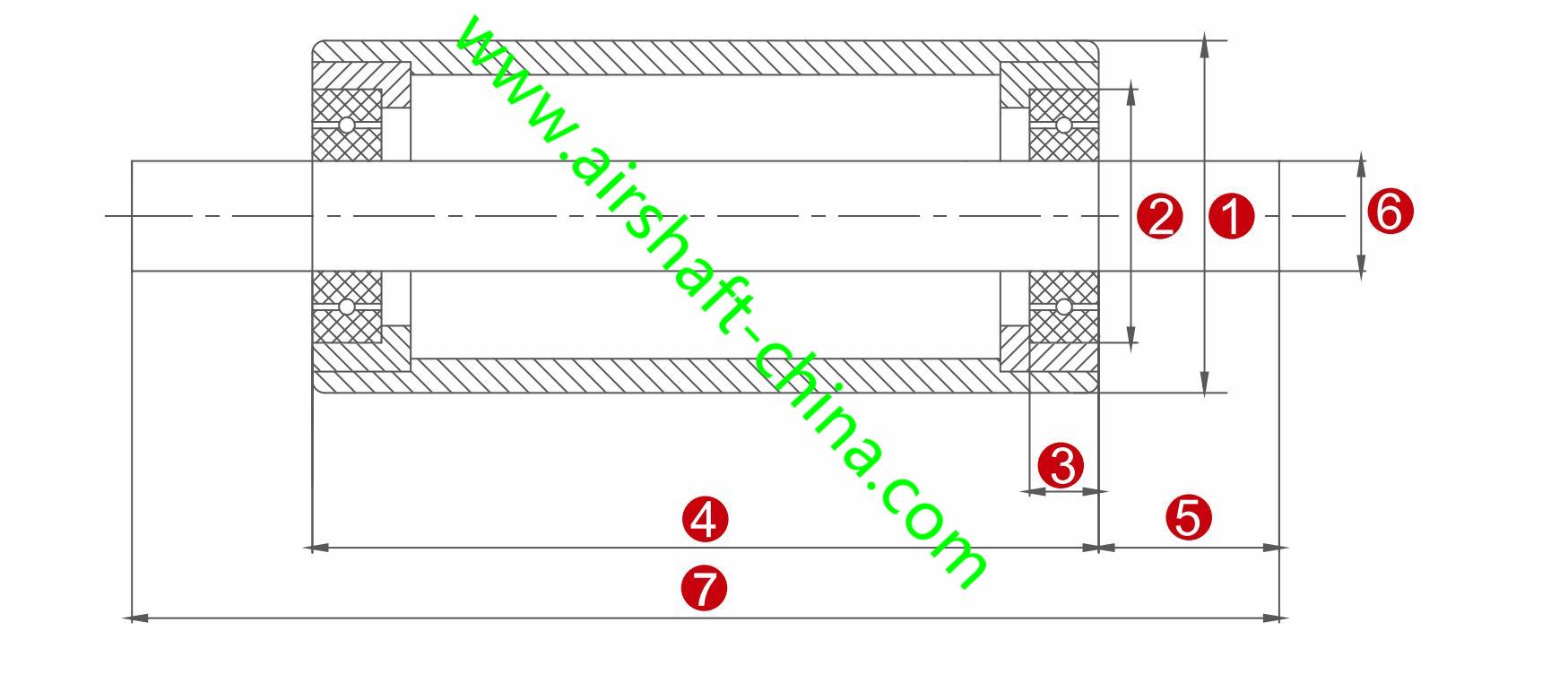

(3) ----Through shaft type Aluminum Guide Roller

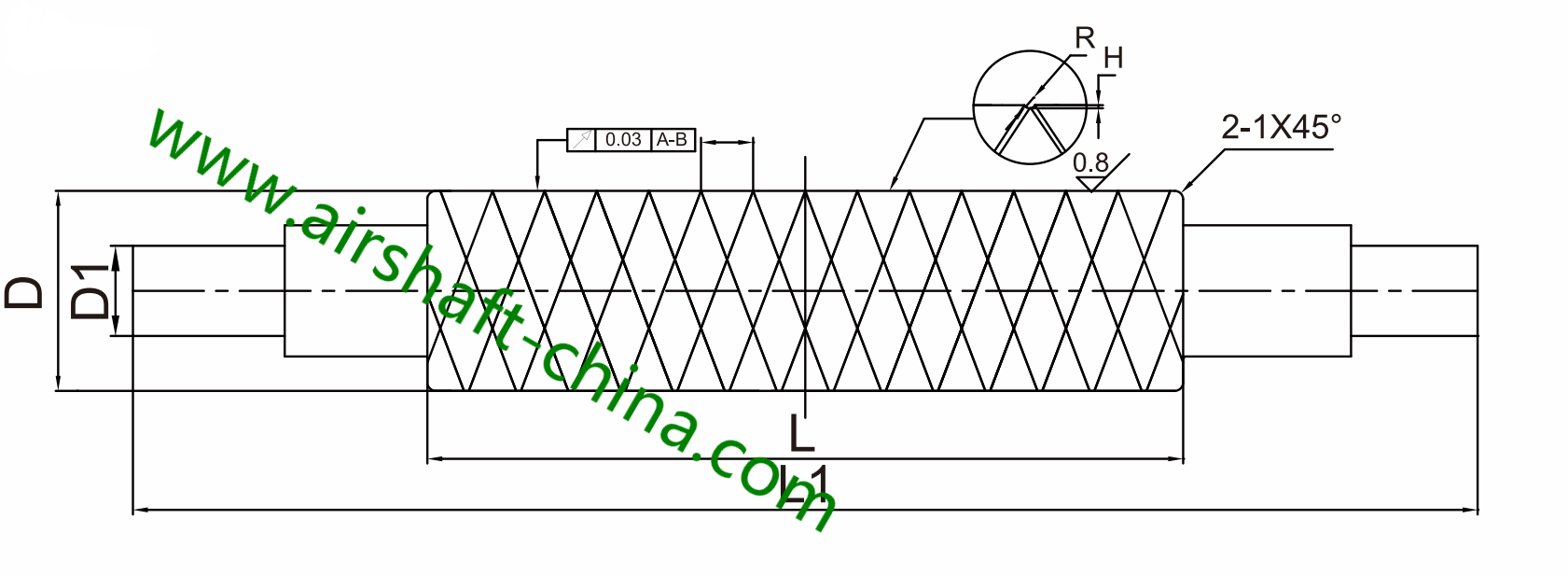

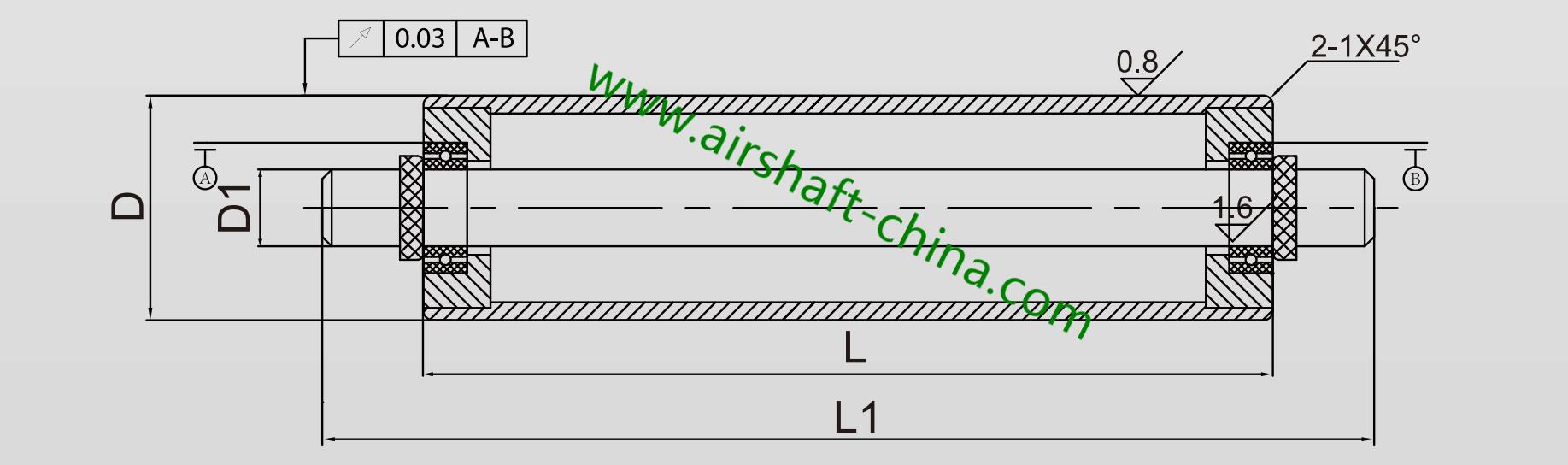

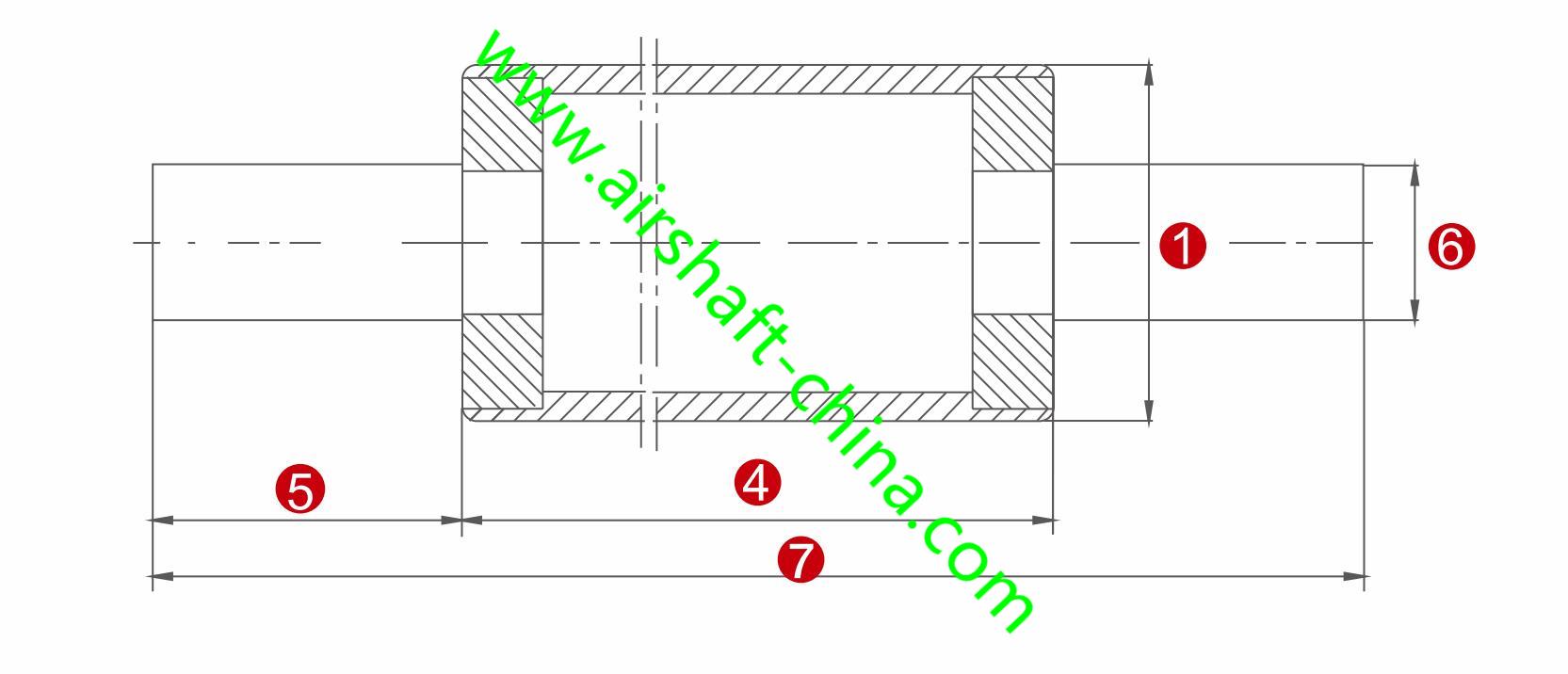

(4) ----With shaft type Aluminum Guide Roller

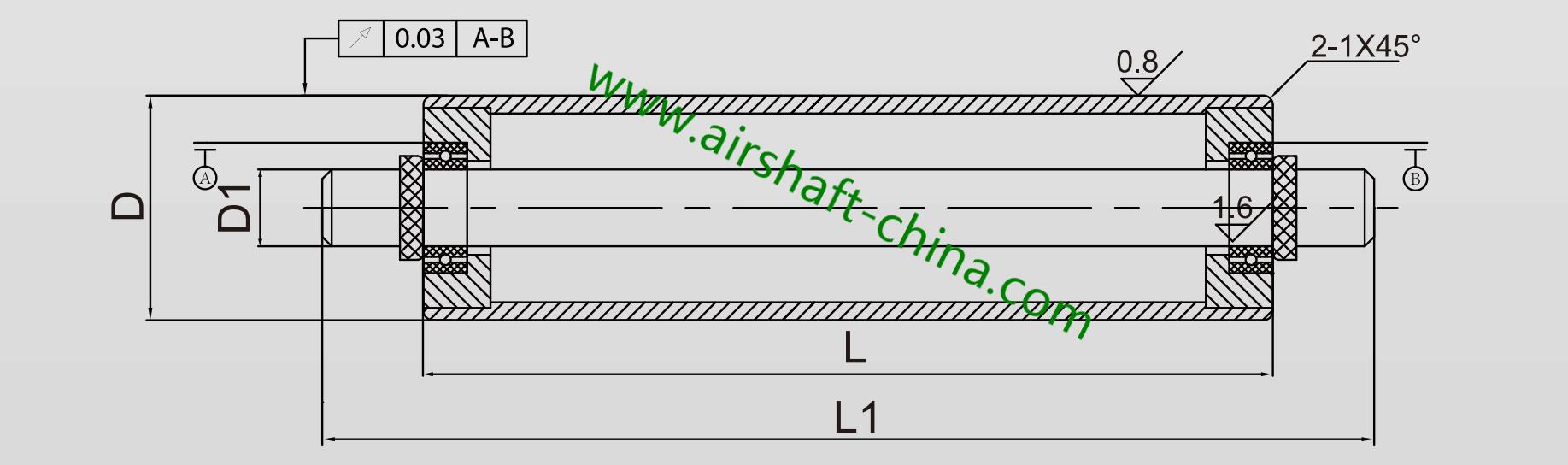

(1) Flat Type Aluminum Guide Roller

(1) Flat Type Aluminum Roller Example

(2) No Shaft Type Aluminum Guide Roller

(2) No Shaft Type Aluminum Roller Example

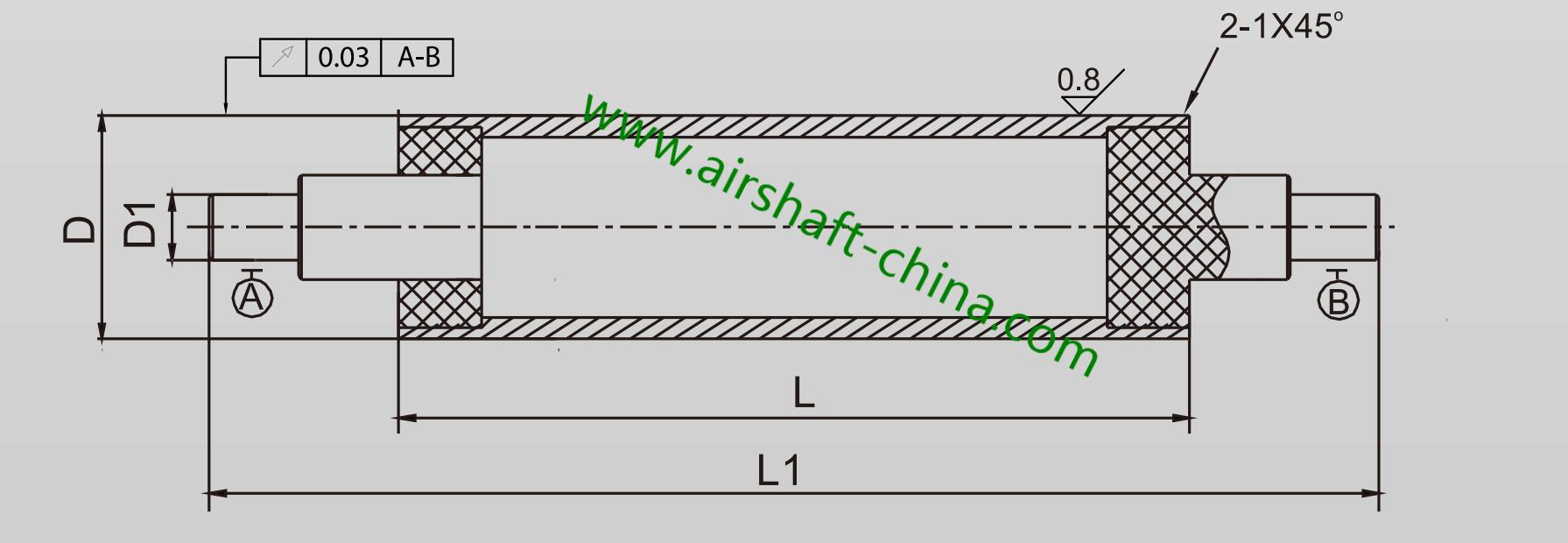

(3)Through Shaft Type Aluminum Guide Roller

(3)Through Shaft Type Aluminum Roller Example

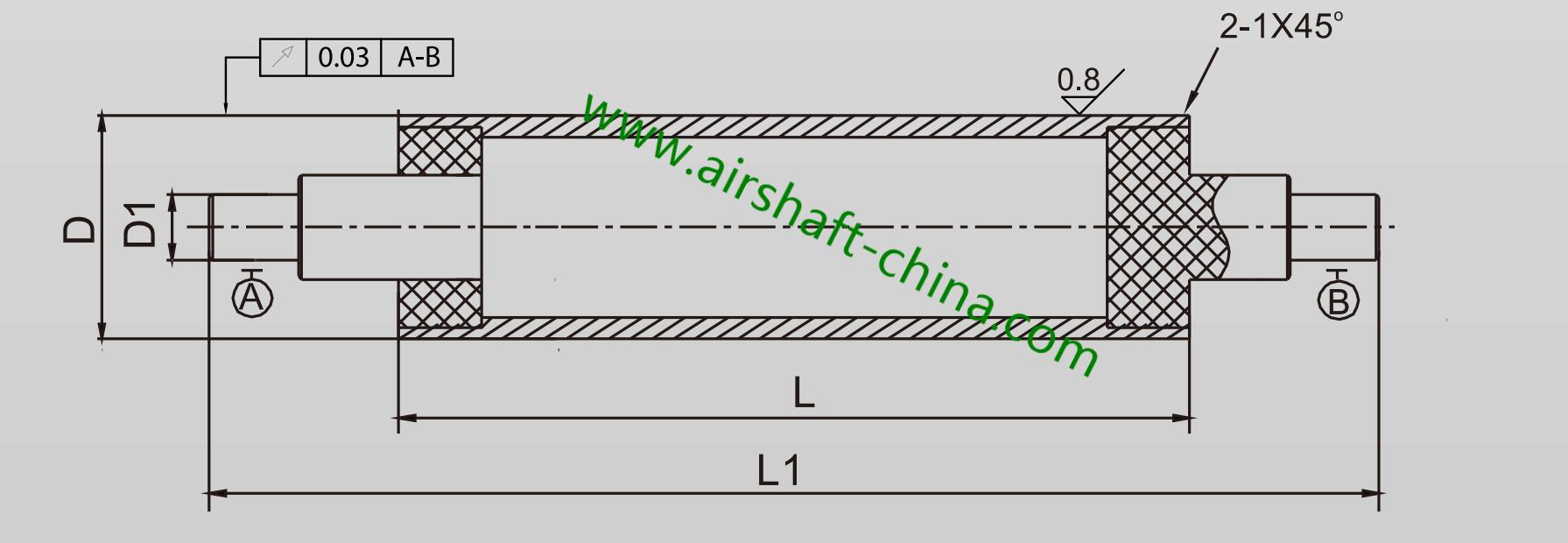

(4) With Shaft Type Aluminum Guide Roller

(4) With Shaft Type Aluminum Guide Roller Example

If you still have question of the type of your Aluminum Guide Roller, You can send the photo to Sales: TerrenceQi@outlook.com

The main types are the following 5 type of the Aluminum Roller.

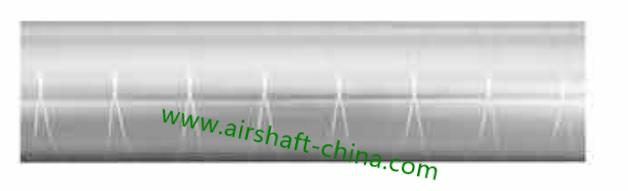

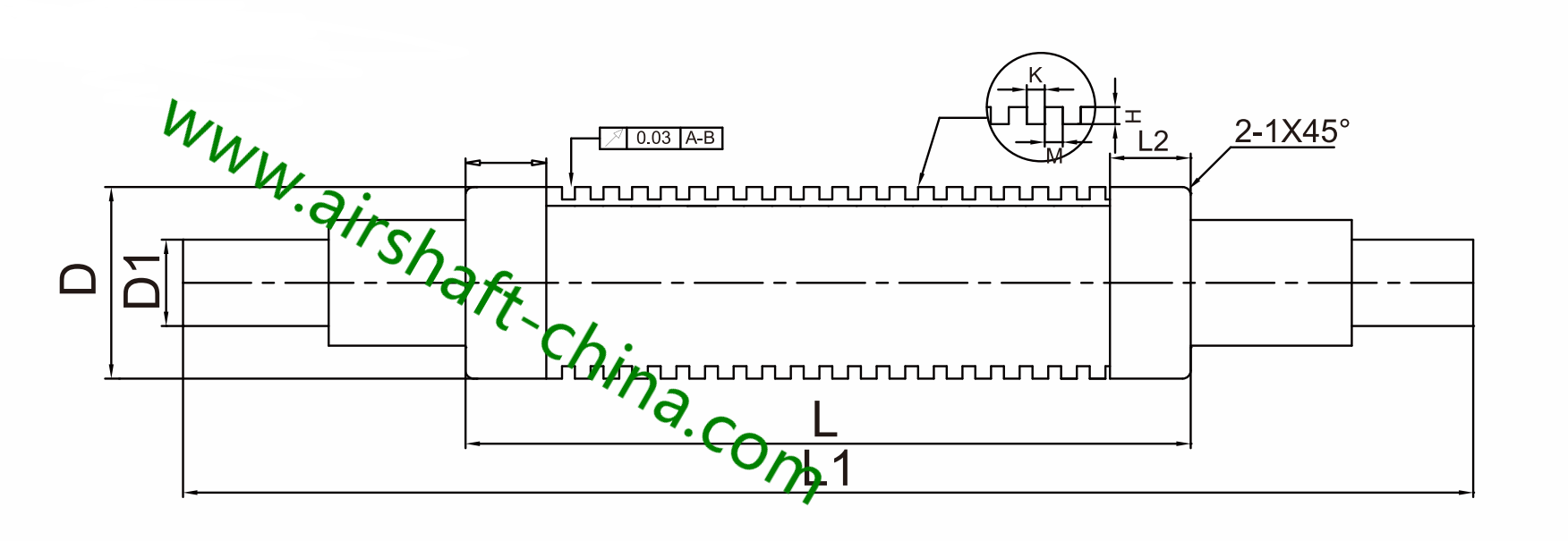

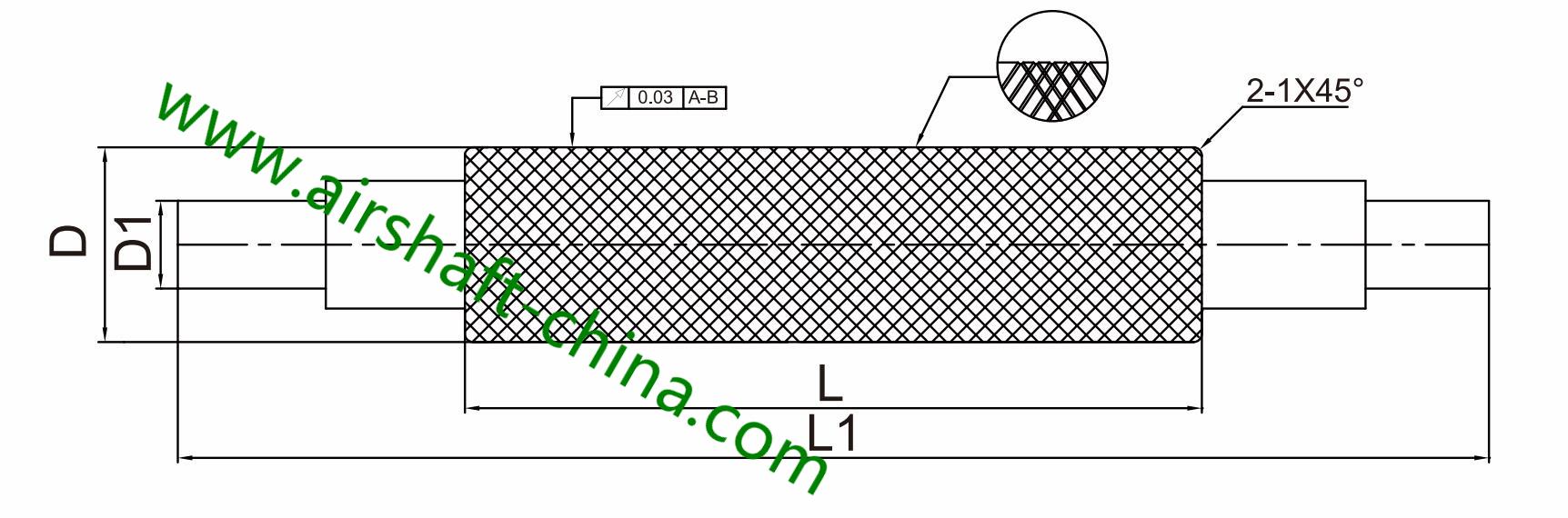

(1)----Cross Line of Aluminum Roller

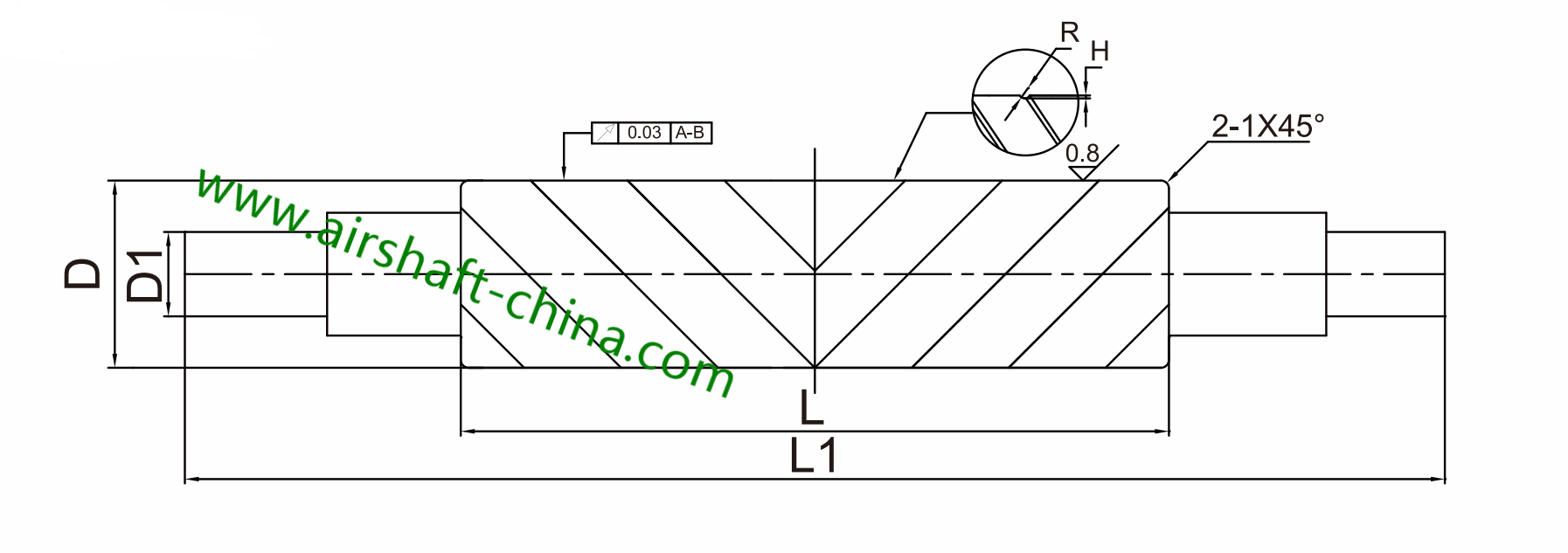

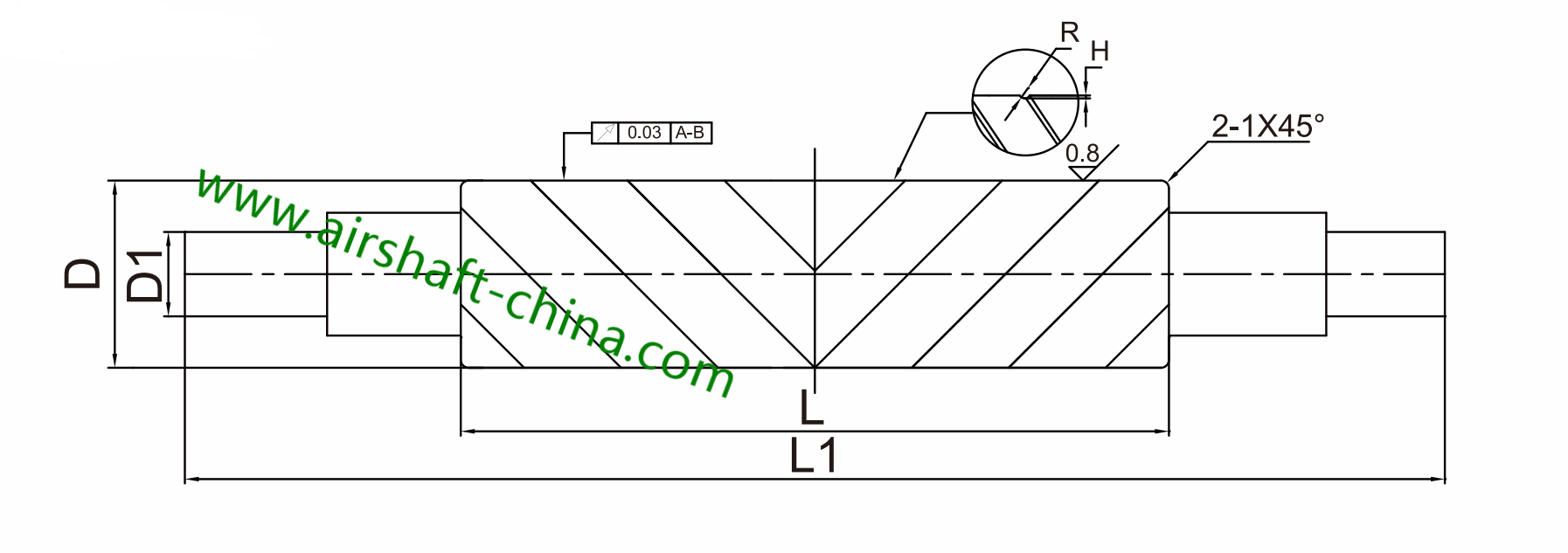

(2)----Center Line of Aluminum Roller

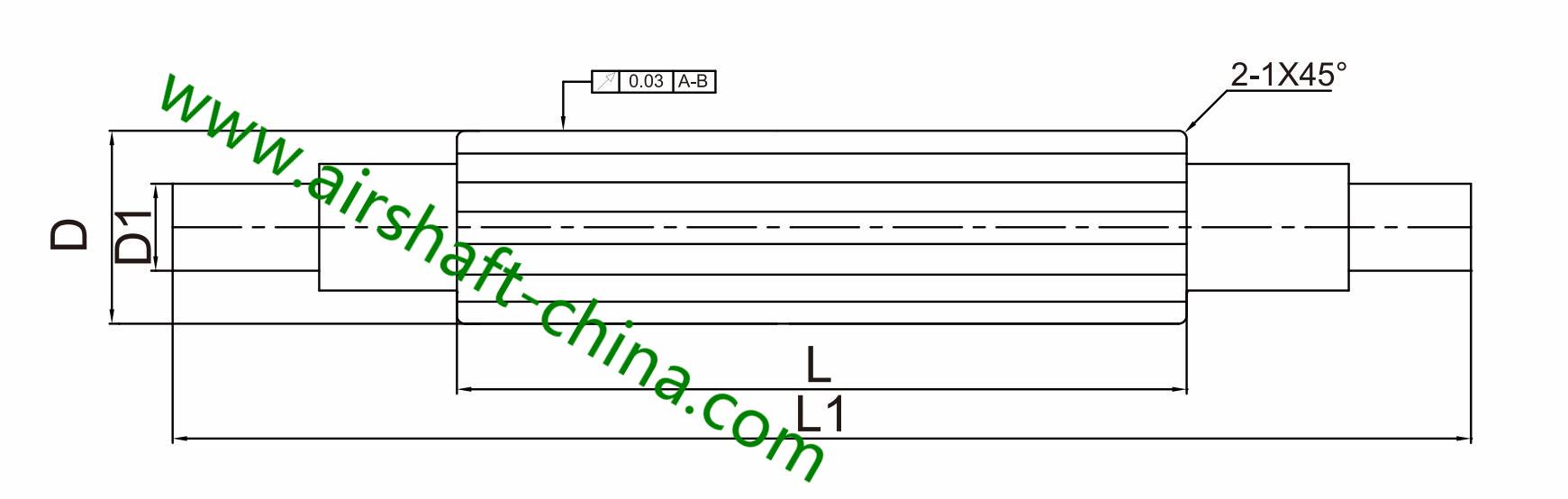

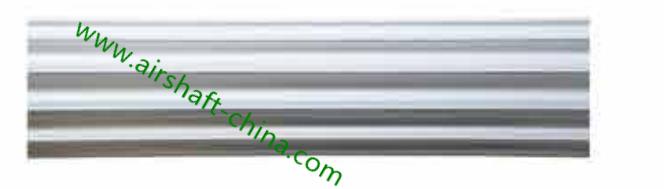

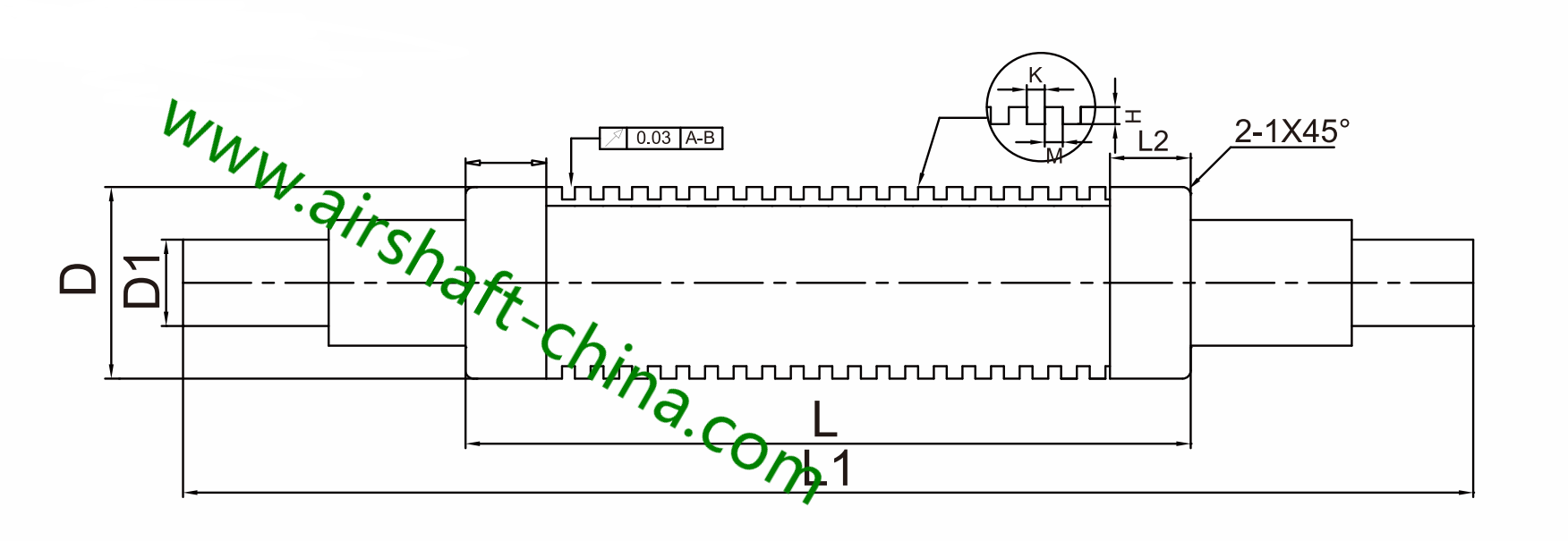

(3)----Grooved Line of Aluminum Roller

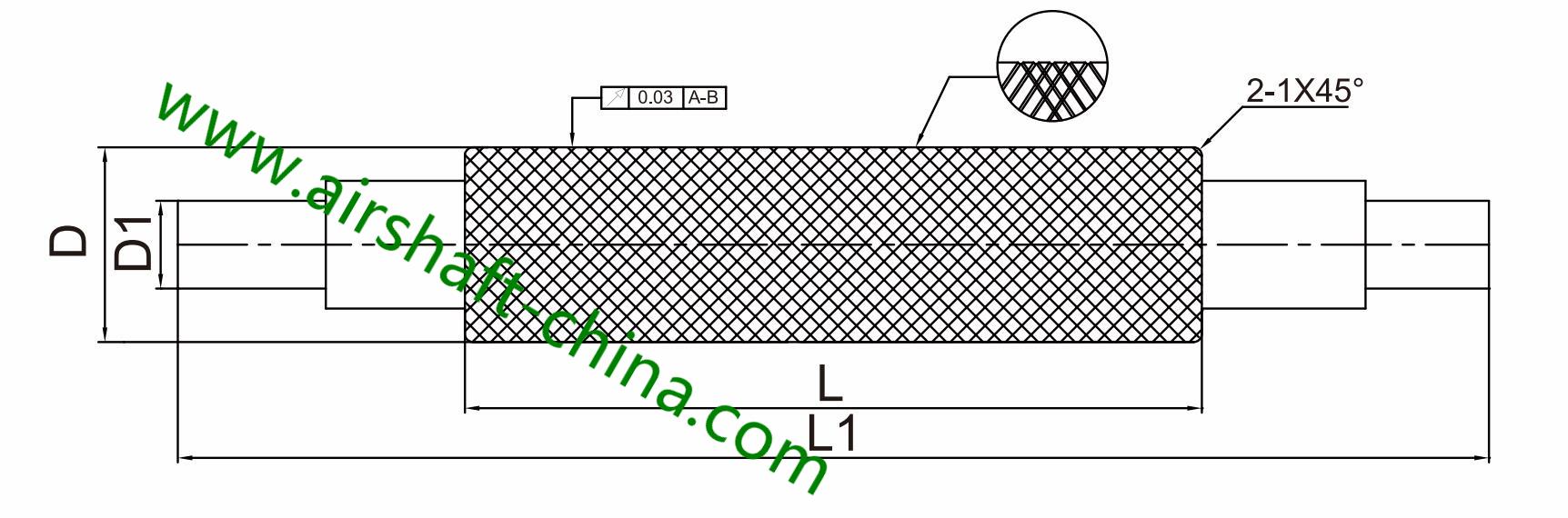

(4)----Anilox Line of Aluminum Roller

(5)----Rolla Line of Aluminum Roller

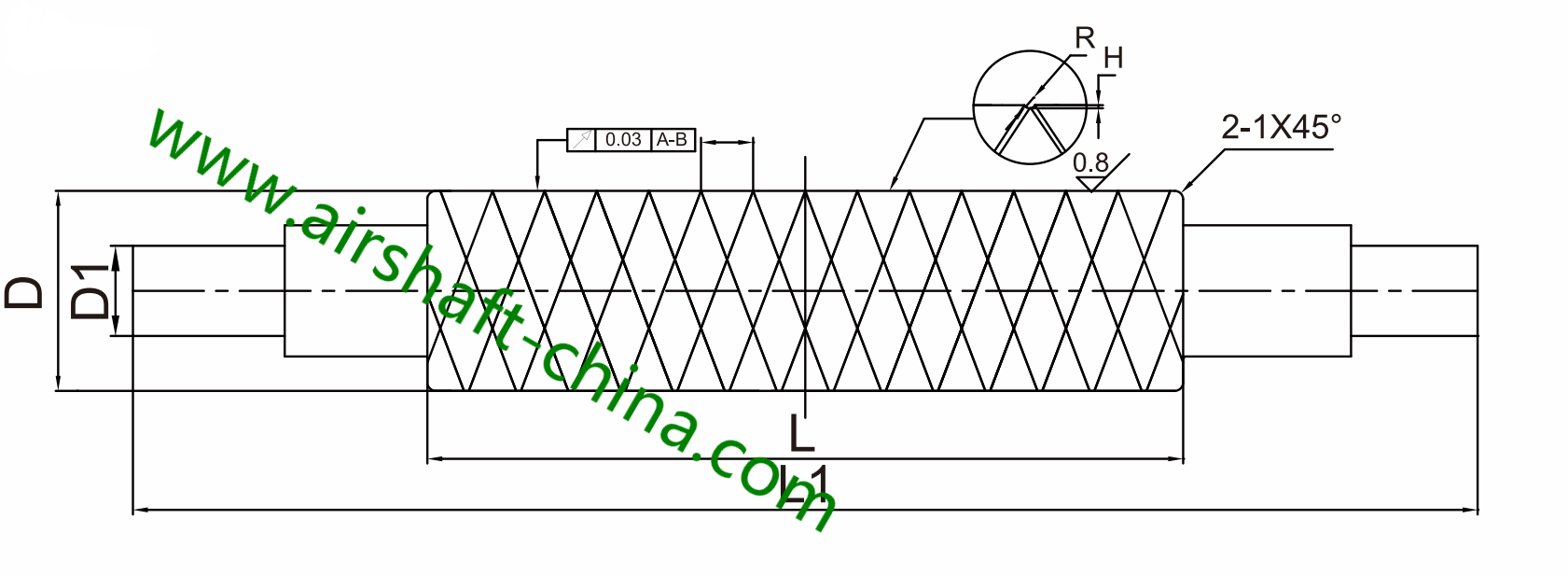

(1) Cross Line of Aluminum Roller

(1) Cross Line of Aluminum Guide Roller Example

(2) Center Line of Aluminum Roller

(2) Center Line of Aluminum Guide Roller Example

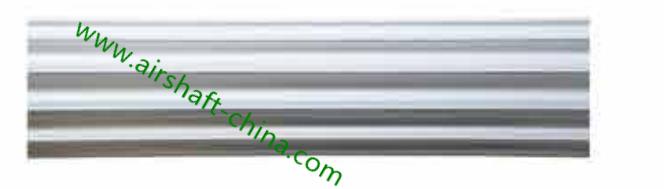

(3) Grooved Line of Aluminum Roller

(3) Grooved Line of Aluminum Guide Roller Example

(4) Anilox Line of Aluminum Roller

(4) Anilox Line of Aluminum Guide Roller Example

(5) Rolla Line of Aluminum Roller

(5) Rolla Line of Aluminum Guide Roller Example

(1) Soft Anodic Oxidation

(2) Hard Brown Anodic Oxidation

(3) Teflon (Anti adhesion and corrossion)

(4) Mirror Effect and Hard Anodic Oxidation

(5) Chrome Plating (also accept Mirror Effect)

Soft Anodic Oxidation of Aluminum Roller

Hard Brown Anodic Oxidation of Aluminum Roller

Teflon of Aluminum Roller

(Anti adhesion and corrossion)

Mirror Effect and Hard Anodic Oxidation of Aluminum Roller

Chrome Plating of Aluminum Roller

(Also Accept Mirror Effect)

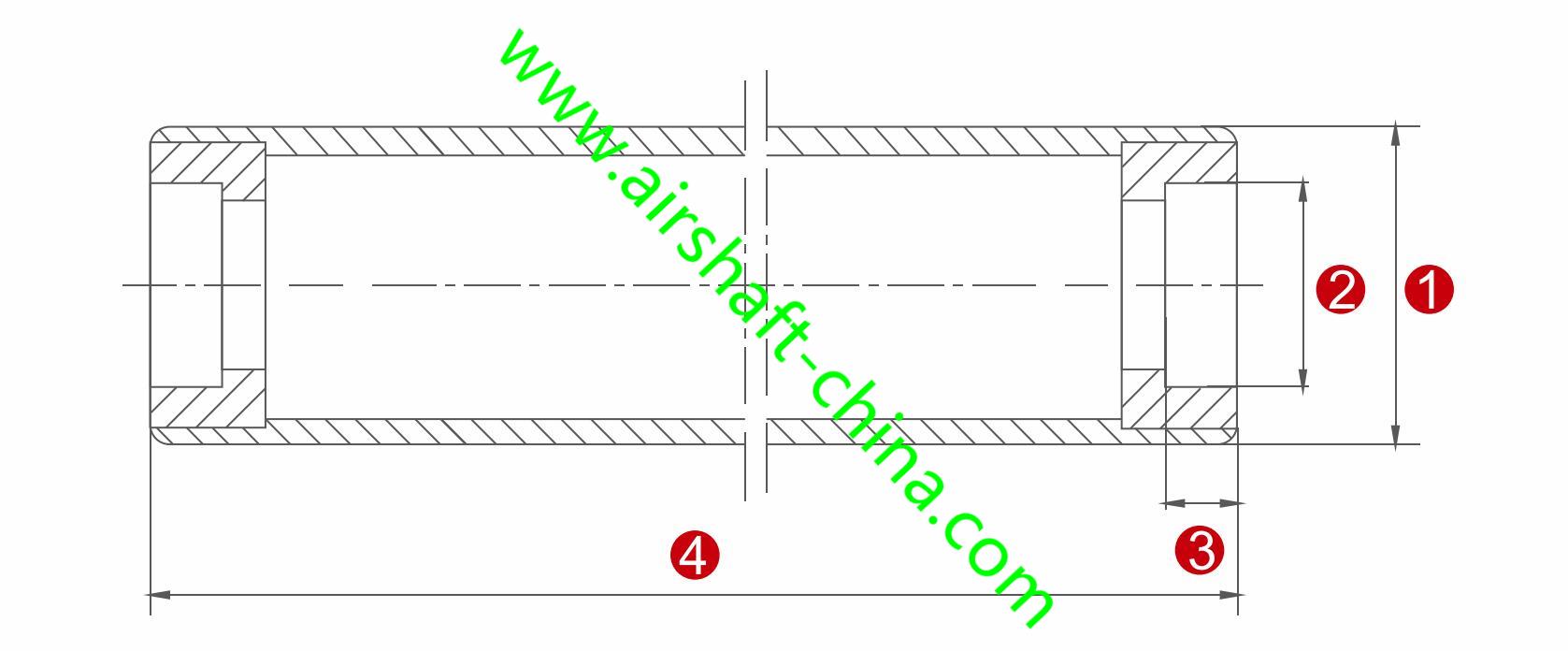

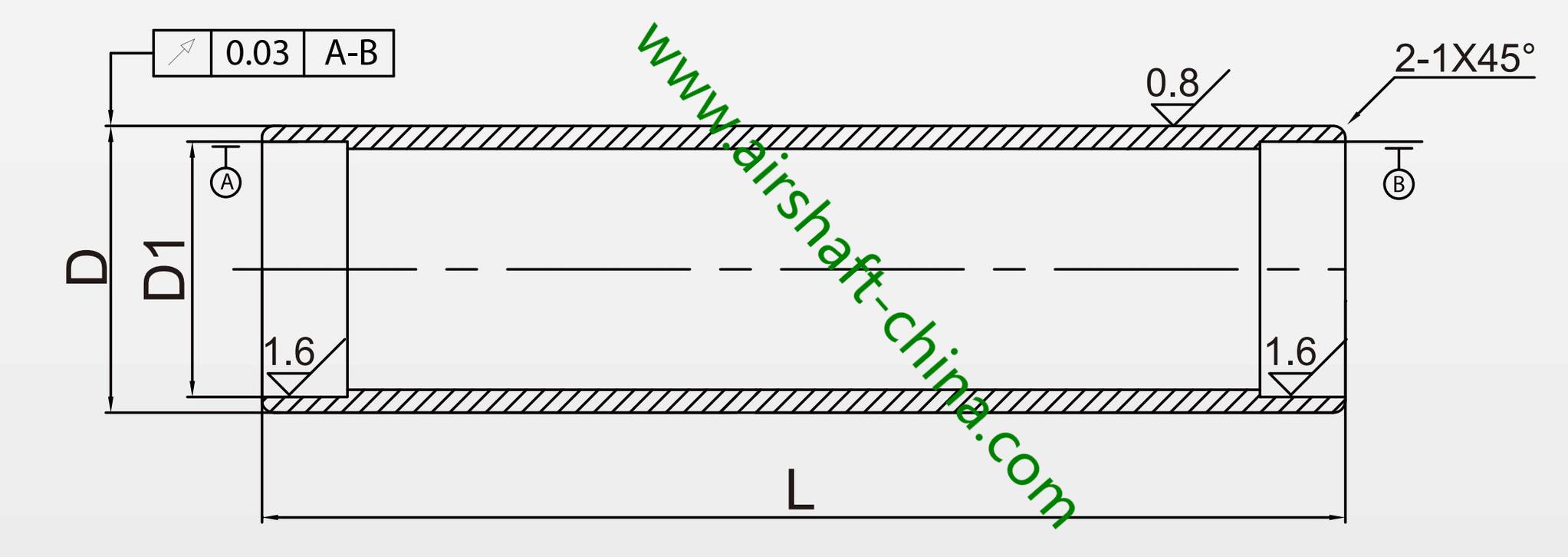

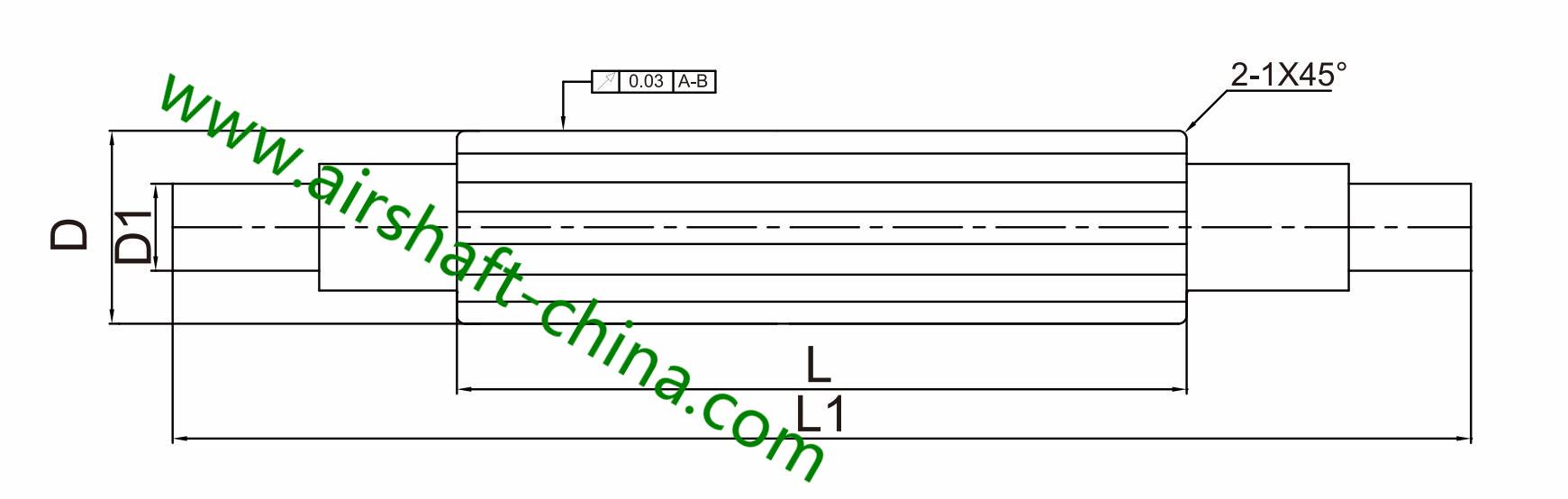

Roller Diameter

Bearing Diameter

Bearing Thickness

Roller Length

Journal Length

Journal Diameter

Total Length

You may fill this drawing example to get a esay quote and TAKE A PHOTO to sales of the original Aluminum Guide Roller.

The good function of the Aluminum Guider Roller depends on the procession machine. We are confident to say, our factory is equipped with the advanced Machines to be able to process the Best Aluminum Guide Roller.

When purchasing an aluminum guide roller, there are several factors to consider to ensure you choose the right product for your specific needs. Here are some important considerations:

1. Application: Determine the specific application for which you require the aluminum guide roller. Different industries and processes have unique requirements, such as conveyor systems, paper manufacturing, printing presses, or material handling. Understanding your application will help you select a roller with the appropriate specifications.

2. Load Capacity: Consider the weight and size of the materials or products that will be supported or guided by the roller. Ensure that the roller you choose has an adequate load capacity to handle the anticipated weight without deformation or failure. It's important to consider both the static load (when the material is stationary) and dynamic load (when it is in motion).

3. Dimensions: Take into account the diameter, length, and shaft size of the roller. The dimensions should be compatible with your equipment or system requirements. Ensure that the roller's size allows for smooth operation and proper fit within the intended setup.

4. Surface Finish: The surface finish of the roller can impact its performance. Consider the required friction or slip characteristics for your application. A smooth surface may be suitable for applications that require low friction, while a textured or knurled surface may provide better grip or traction.

5. Material Compatibility: Evaluate the compatibility of the roller material with the materials being guided or handled. Ensure that the aluminum roller is resistant to corrosion, wear, or any chemical interactions that may occur in your specific application. Compatibility is especially important in industries where rollers come into contact with harsh chemicals or abrasive substances.

6. Temperature and Environment: Consider the operating temperature range and environmental conditions in which the roller will be used. Aluminum rollers can withstand a wide temperature range, but extreme temperatures or specific environmental factors like moisture, humidity, or exposure to chemicals may require additional protective coatings or materials.

7. Quality and Durability: Assess the overall quality and durability of the roller. Look for reputable manufacturers or suppliers known for producing high-quality rollers. Consider factors such as build quality, precision, and reliability to ensure a long-lasting and dependable product.

By considering these factors, you can make an informed decision when purchasing an aluminum guide roller that meets your needs and provides efficient and reliable performance.

Our goal is to make customer feel satisfied about the quality and price of the Aluminum Guide Roller and Airshaft!

We welcome if you would like to have an online factory tour!

It only take 1 minute!

This is the video of Our Factory will fully equipped Airshaft and Aluminum Roller Manufactuering Devices.

Using wechat and Scan this code to talk with Airshaft Sales!

Mr Terrence

Using Whatsapp and Scan this code to talk with Airshaft Sales!

Mr Terrence

The minimum concentricity of this Aluminum Roller can reach 0.02mm.

The surface treatment of Aluminum Guide Roller can reach RA 0.8, Mirror effect could reach RA 0.4.

Aluminum Roller is widely used in every industry, especially Printing, Packing, Plastic, Paper, Glass, Textile..........

The aluminum roller serves various functions depending on the specific context or industry. Here are a few common applications and uses of aluminum rollers:

1. Printing and Graphics: In the printing industry, aluminum rollers are used in printing presses. They help transfer ink from the printing plate to the paper or other printing substrates. The smooth surface of the roller ensures even ink distribution and helps create high-quality prints.

2. Conveying and Processing: Aluminum rollers are often used in conveyor systems for material handling and processing. They can be employed in industries such as manufacturing, packaging, and food processing to transport goods or materials along a production line. The lightweight nature of aluminum makes it suitable for applications where reduced weight and ease of movement are desired.

3. Laminating and Coating: Aluminum rollers find use in laminating and coating processes. For example, in the production of laminated films, the roller applies pressure to bond layers together and ensure uniform adhesion. Similarly, in coating applications, such as applying adhesives or coatings to surfaces, the roller assists in spreading and smoothing the coating material.

4. Industrial Applications: Aluminum rollers are utilized in various industrial processes, such as calendering (smoothing and flattening materials like paper or plastic), embossing (creating textures or patterns on surfaces), and metalworking (rolling sheets or bars). They can also be used in machinery for tasks like guiding, tensioning, or supporting materials during manufacturing operations.

5. Wrinkle Removal and Surface Treatment: In certain applications, aluminum rollers are employed to remove wrinkles or imperfections from materials. For instance, in the textile industry, fabric is passed through heated aluminum rollers to smoothen the surface and remove creases. Additionally, aluminum rollers can be used for other surface treatments, such as burnishing or polishing.

It's important to note that the specific design, size, and surface properties of aluminum rollers can vary based on the intended application.

(1) ----Flat Tube type Aluminum Guide Roller

(2) ----No shaft type Aluminum Guide Roller

(3) ----Through shaft type Aluminum Guide Roller

(4) ----With shaft type Aluminum Guide Roller

(1) Flat Type Aluminum Guide Roller

(1) Flat Type Aluminum Roller Example

(2) No Shaft Type Aluminum Guide Roller

(2) No Shaft Type Aluminum Roller Example

(3)Through Shaft Type Aluminum Guide Roller

(3)Through Shaft Type Aluminum Roller Example

(4) With Shaft Type Aluminum Guide Roller

(4) With Shaft Type Aluminum Guide Roller Example

If you still have question of the type of your Aluminum Guide Roller, You can send the photo to Sales: TerrenceQi@outlook.com

The main types are the following 5 type of the Aluminum Roller.

(1)----Cross Line of Aluminum Roller

(2)----Center Line of Aluminum Roller

(3)----Grooved Line of Aluminum Roller

(4)----Anilox Line of Aluminum Roller

(5)----Rolla Line of Aluminum Roller

(1) Cross Line of Aluminum Roller

(1) Cross Line of Aluminum Guide Roller Example

(2) Center Line of Aluminum Roller

(2) Center Line of Aluminum Guide Roller Example

(3) Grooved Line of Aluminum Roller

(3) Grooved Line of Aluminum Guide Roller Example

(4) Anilox Line of Aluminum Roller

(4) Anilox Line of Aluminum Guide Roller Example

(5) Rolla Line of Aluminum Roller

(5) Rolla Line of Aluminum Guide Roller Example

(1) Soft Anodic Oxidation

(2) Hard Brown Anodic Oxidation

(3) Teflon (Anti adhesion and corrossion)

(4) Mirror Effect and Hard Anodic Oxidation

(5) Chrome Plating (also accept Mirror Effect)

Soft Anodic Oxidation of Aluminum Roller

Hard Brown Anodic Oxidation of Aluminum Roller

Teflon of Aluminum Roller

(Anti adhesion and corrossion)

Mirror Effect and Hard Anodic Oxidation of Aluminum Roller

Chrome Plating of Aluminum Roller

(Also Accept Mirror Effect)

Roller Diameter

Bearing Diameter

Bearing Thickness

Roller Length

Journal Length

Journal Diameter

Total Length

You may fill this drawing example to get a esay quote and TAKE A PHOTO to sales of the original Aluminum Guide Roller.

The good function of the Aluminum Guider Roller depends on the procession machine. We are confident to say, our factory is equipped with the advanced Machines to be able to process the Best Aluminum Guide Roller.

When purchasing an aluminum guide roller, there are several factors to consider to ensure you choose the right product for your specific needs. Here are some important considerations:

1. Application: Determine the specific application for which you require the aluminum guide roller. Different industries and processes have unique requirements, such as conveyor systems, paper manufacturing, printing presses, or material handling. Understanding your application will help you select a roller with the appropriate specifications.

2. Load Capacity: Consider the weight and size of the materials or products that will be supported or guided by the roller. Ensure that the roller you choose has an adequate load capacity to handle the anticipated weight without deformation or failure. It's important to consider both the static load (when the material is stationary) and dynamic load (when it is in motion).

3. Dimensions: Take into account the diameter, length, and shaft size of the roller. The dimensions should be compatible with your equipment or system requirements. Ensure that the roller's size allows for smooth operation and proper fit within the intended setup.

4. Surface Finish: The surface finish of the roller can impact its performance. Consider the required friction or slip characteristics for your application. A smooth surface may be suitable for applications that require low friction, while a textured or knurled surface may provide better grip or traction.

5. Material Compatibility: Evaluate the compatibility of the roller material with the materials being guided or handled. Ensure that the aluminum roller is resistant to corrosion, wear, or any chemical interactions that may occur in your specific application. Compatibility is especially important in industries where rollers come into contact with harsh chemicals or abrasive substances.

6. Temperature and Environment: Consider the operating temperature range and environmental conditions in which the roller will be used. Aluminum rollers can withstand a wide temperature range, but extreme temperatures or specific environmental factors like moisture, humidity, or exposure to chemicals may require additional protective coatings or materials.

7. Quality and Durability: Assess the overall quality and durability of the roller. Look for reputable manufacturers or suppliers known for producing high-quality rollers. Consider factors such as build quality, precision, and reliability to ensure a long-lasting and dependable product.

By considering these factors, you can make an informed decision when purchasing an aluminum guide roller that meets your needs and provides efficient and reliable performance.

Our goal is to make customer feel satisfied about the quality and price of the Aluminum Guide Roller and Airshaft!

We welcome if you would like to have an online factory tour!

It only take 1 minute!

This is the video of Our Factory will fully equipped Airshaft and Aluminum Roller Manufactuering Devices.

Using wechat and Scan this code to talk with Airshaft Sales!

Mr Terrence

Using Whatsapp and Scan this code to talk with Airshaft Sales!

Mr Terrence