Factory Standard

Copper/ Stainless Steel

/

1 Days for Normal Order, Hurry Order is Negotiable

Wooden Box / Paper Box / Paper tube / Bubble Film

By Sea / By Air / By Train / By Fedex or other Express way

ISO9000/CE/ROHS/Certificate of Origin

Technical Video Support

T/T/Credit Card/Paypal.....

| Availability: | |

|---|---|

| Quantity: | |

| PDF Export | |

It is the most important part of the Airshaft. Because in most case, the Air leaking of the Air valve is caused by the poor quality of the Airvalve is Airshaft.

In most case, the other Airshaft suppliers are using Air valve made by Copper. It was once a good choice in the past years. For reason of it lower cost. However, we upgrade it into Stainless Steel. It is a better choice, and our experiment data will show where is its advantage and how.

(the experiment data will be shown in the following pages)

Arrow head

Horn Head

The yellow type Air Inflator is used together with Arrow head Air Valve in Pneumatic Shaft.

The gray type Air Inflator is used together with Horn Head Air Valve in pneumatic shaft.

1. Experiment reason

To find a better material to avoid Air leaking in Airshaft

2. Experiment Time and Staff

8th, Aug, 2020.-------8th, Jan, 2021 (Lasting for Half a year)

Factory technical manager and Quality Control Team

3. Experiment Operation

(1) 10, 000pcs copper Air valve and 10, 000 pcs Stainless steel Airvalve Valve for Air inflation to check random leaking rate

(2) Mass Air inflation test of After finishing 10,000 times air inflation and deflation for each air valve. And to see which how many air vlave is still in good using situation and NOT LEAK AIR.

(1000 pcs copper air valves and 1000 pcs Stainless steel air valves are used in this test)

4. Experiment Results

Copper Air Valve:

(1) Air leaking possibility without using====1.5%=1.5/100

(2) Air leaking situation after 10,000 times inflation and deflation==== 10%=10/100

Stainless Steel Air Valve :

(1) Air leaking possibility without using====1/3000

(2) Air leaking situation after 10,000 times inflation and deflation====0%

Additional Experience:

Copper Airshaft valve for reason of it raw material, it is more easily for broken.

Broken mean totally broken by Half, it is a situation happened in a certain case.

SS Air shaft valve can avoid this situation.

Note: The Air valve are all in good situation before Inflation and Deflation Test. They are assembled in Airshaft to simulate the real using situation.

There are a lot of type of air shaft valves in market.

If you would like to make the purchase, you can compare the dimension with our standard airshaft part.

If still there is something you not see, you can send the photo and make a simple dimension drawing to sales!

If there are still something you not see in our webstie,

Please take the photo and send to Sales!

We are confident to GET ALL THINGS you need!

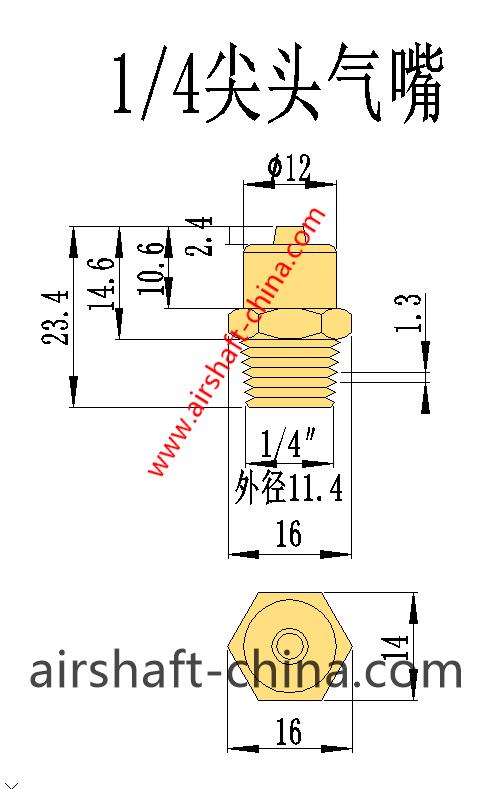

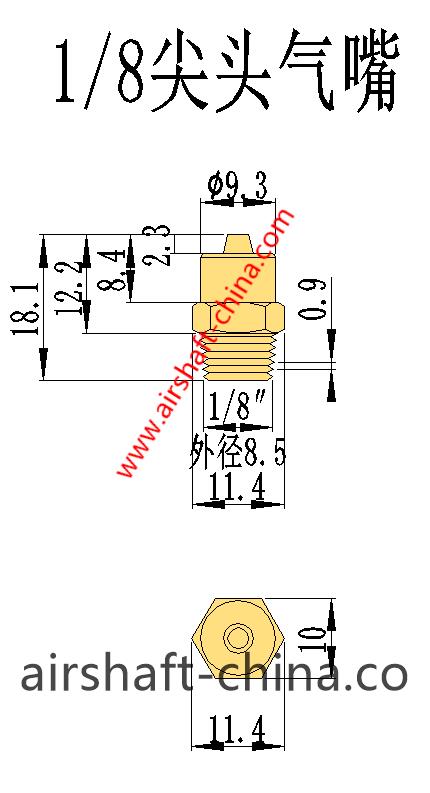

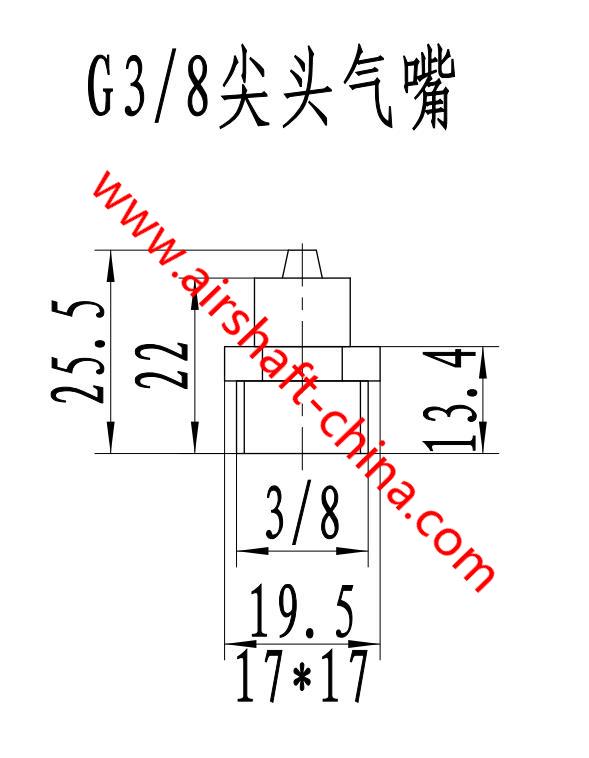

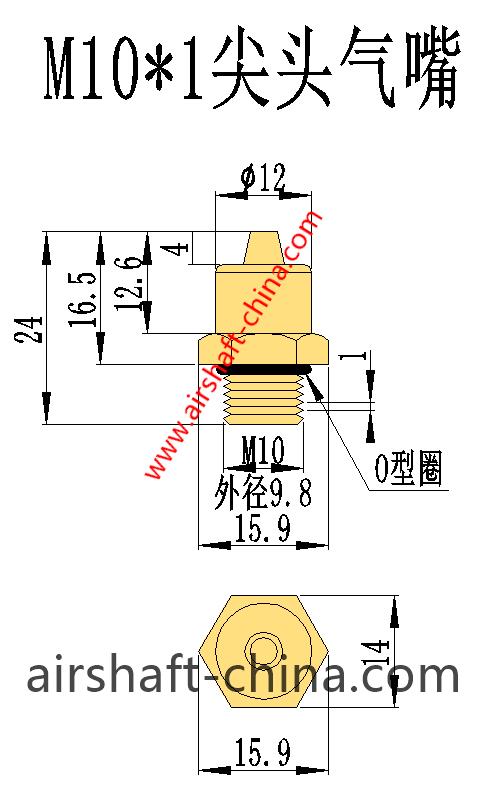

Standard Dimension of the Air valves in Air shaft.

Download this link to get all types drawing of the air inflation valves.

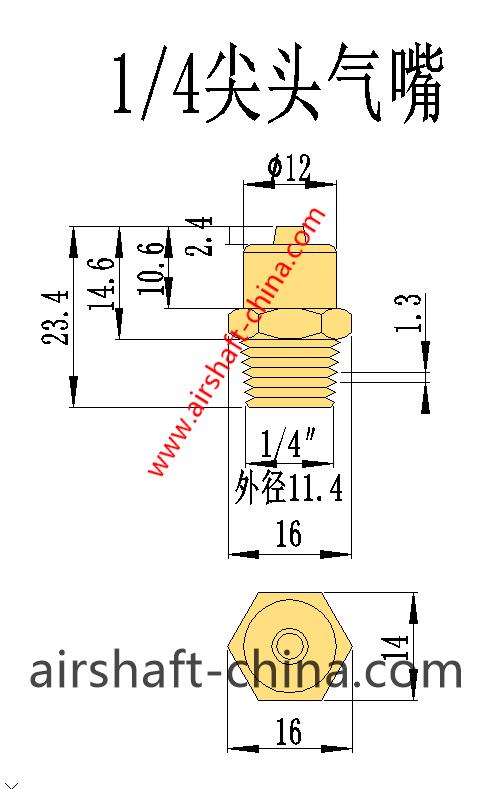

1/4 arrow

Air shaft valve

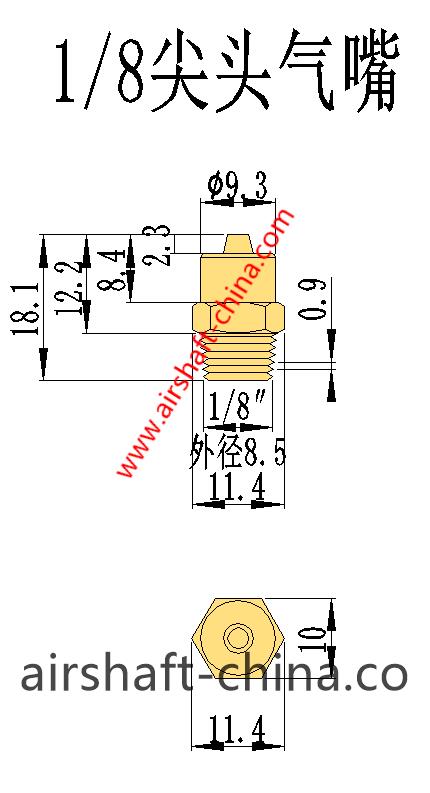

1/8 arrow

Air shaft valve

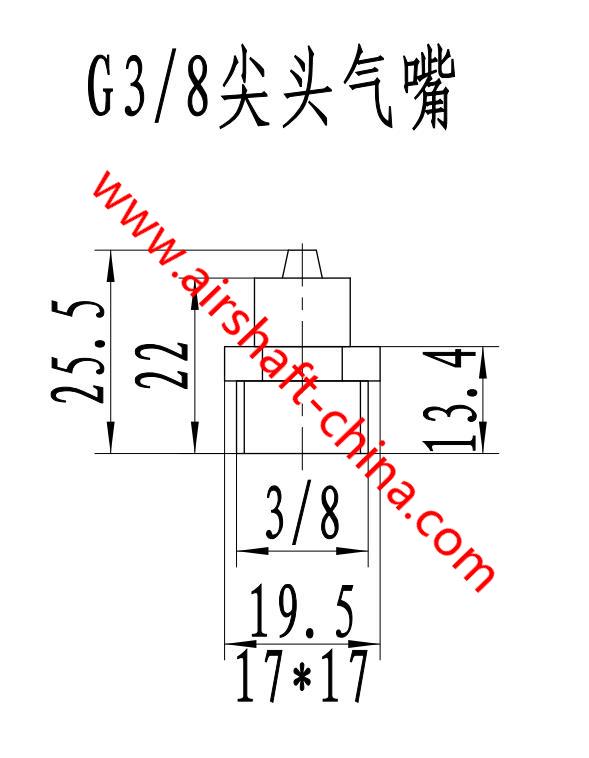

3/8 arrow

Air shaft valve

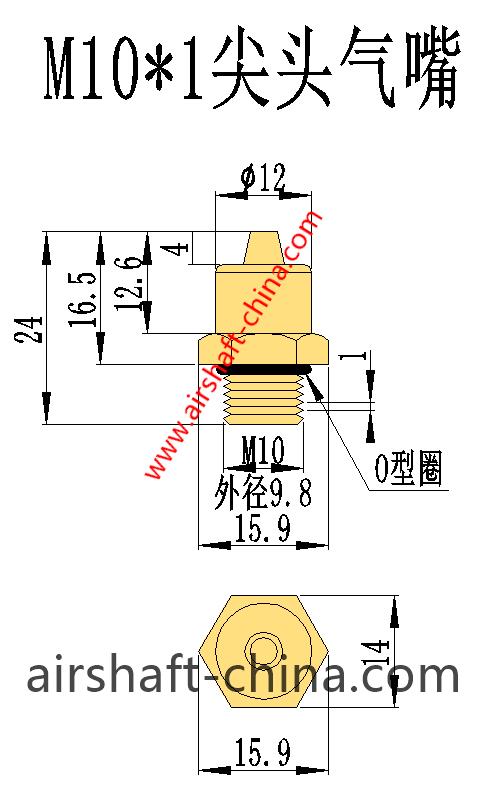

M10x1 arrow

Air shaft valve

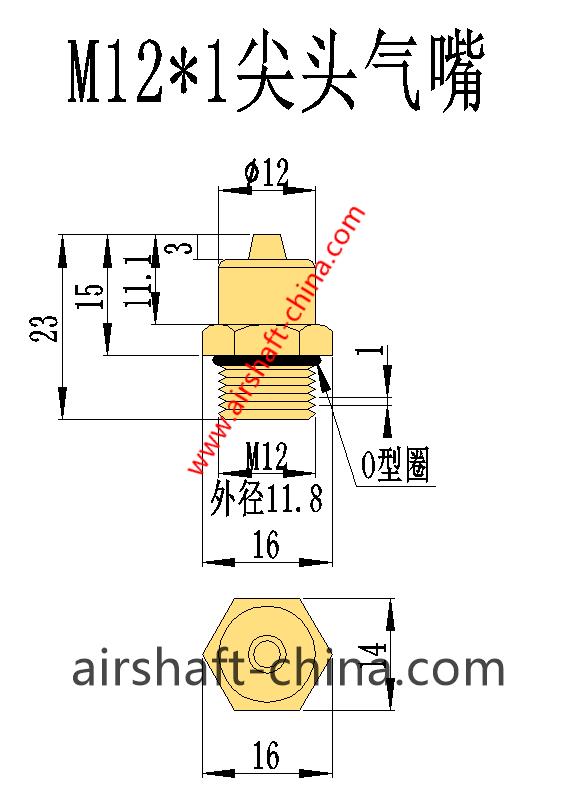

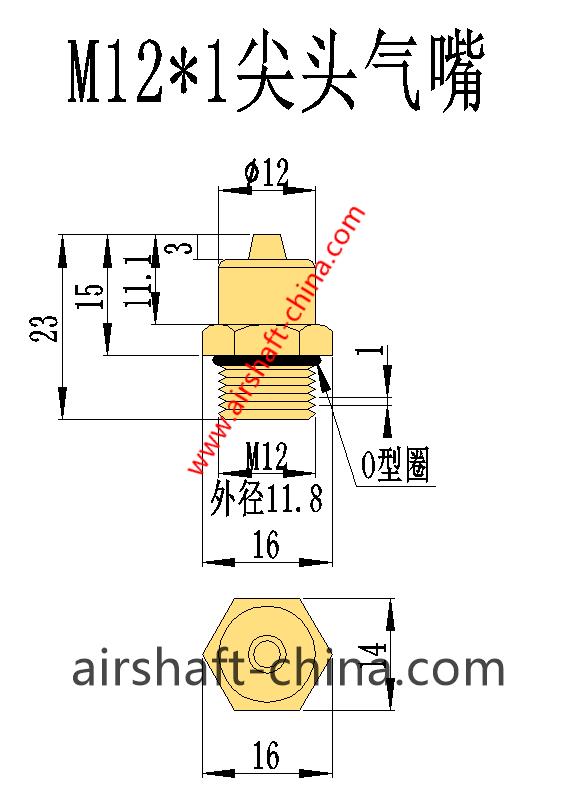

M12x1 arrow

Air shaft valve

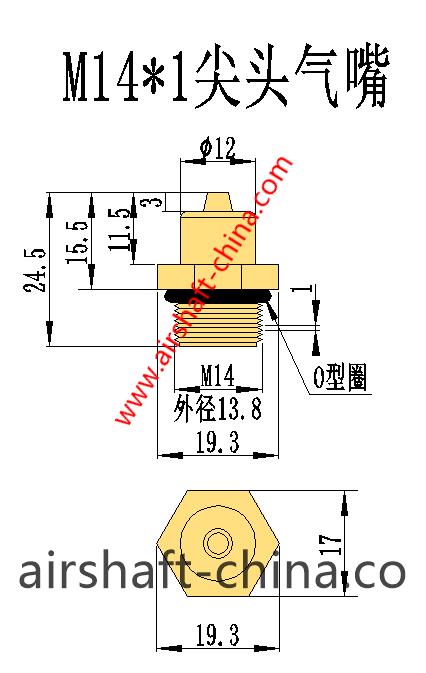

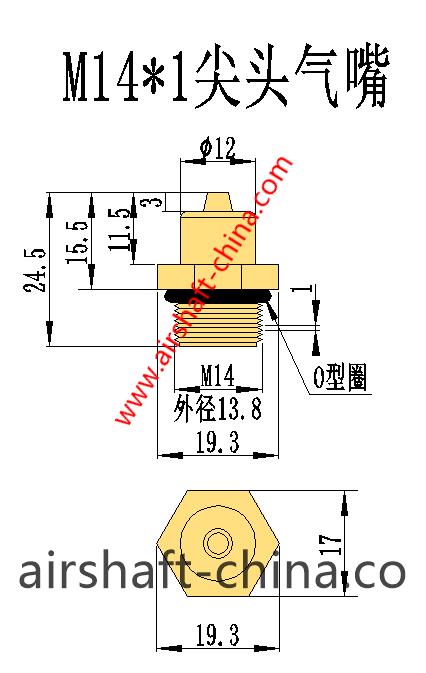

M14x1 arrow 1

Air shaft valve

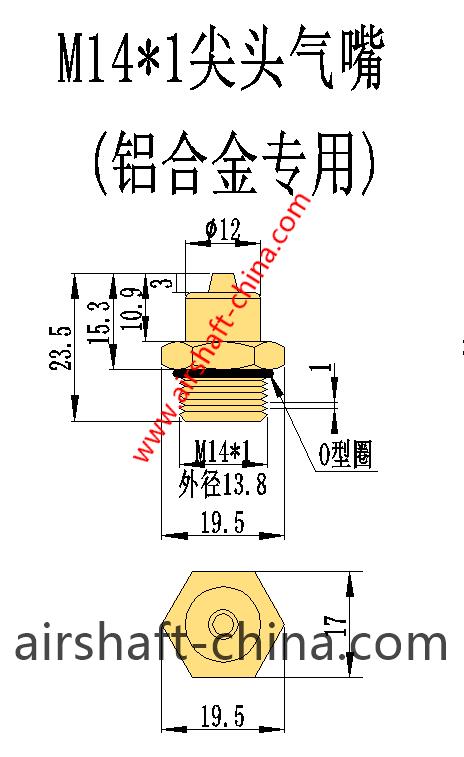

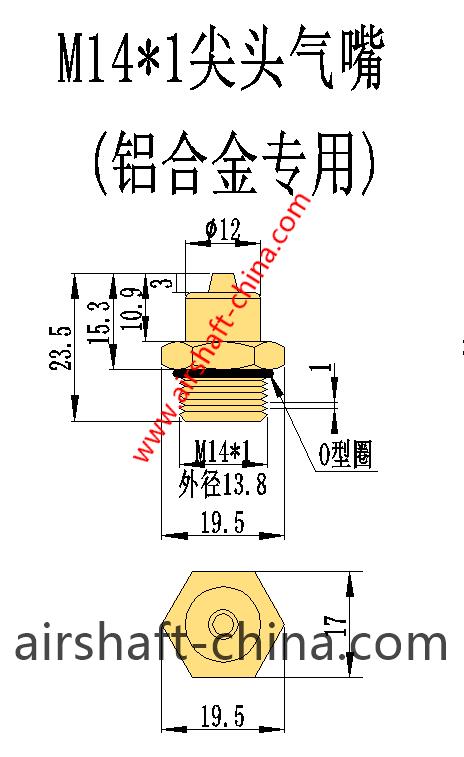

M14x1 arrow 2

Air shaft valve

M14x1.5 arrow

Air shaft valve

There are also some M16 Air valve, can contact sales for more information.

The air valve is a crucial component of the air expanding shaft system. Here's some information about it:

Function: The air valve is responsible for inflating or deflating the air expanding shaft, controlling its expansion and contraction. When inflated, the shaft grips the core of the roll securely, allowing for rotation and unwinding of the material. When deflated, the roll can be easily removed or replaced.

Design and Operation: The air valve is typically mounted on the air expanding shaft and connected to a source of compressed air. It features a mechanism that allows for controlled inflation and deflation of the shaft. The valve can be manually operated or automated, depending on the specific application and requirements.

Control Methods: The air valve of an air expanding shaft can be operated through various control methods, including:

(1) Manual Control: This involves using a manual valve or lever to regulate the airflow into the shaft. The operator manually adjusts the valve to inflate or deflate the shaft as needed.

(2) Pneumatic Control: In this case, the air valve is connected to a pneumatic control system that automatically regulates the airflow based on preset parameters or feedback from sensors. This allows for precise and consistent control over the expansion and contraction of the shaft.

Safety Features: Air valves in air expanding shaft systems often incorporate safety features to prevent accidental deflation of the shaft. These features can include locking mechanisms or pressure sensors that ensure the shaft remains inflated during operation.

Applications: Air expanding shafts with air valves are commonly used in industries such as printing, packaging, converting, and paper manufacturing. They provide efficient and reliable support for rolls of material, allowing for smooth unwinding or rewinding processes. So, it is very important to choose a reliable air valve during using the air shaft.

Our goal is to make customer feel satisfied about the quality and price of the Airshaft!

We welcome if you would like to have an online factory tour!

It only take 1 minute!

This is the video of Our Factory will fully equipped Airshaft Manufactuering Devices.

Using wechat and Scan this code to talk with Airshaft Sales!

Mr Terrence

Using Whatsapp and Scan this code to talk with Airshaft Sales!

Mr Terrence

It is the most important part of the Airshaft. Because in most case, the Air leaking of the Air valve is caused by the poor quality of the Airvalve is Airshaft.

In most case, the other Airshaft suppliers are using Air valve made by Copper. It was once a good choice in the past years. For reason of it lower cost. However, we upgrade it into Stainless Steel. It is a better choice, and our experiment data will show where is its advantage and how.

(the experiment data will be shown in the following pages)

Arrow head

Horn Head

The yellow type Air Inflator is used together with Arrow head Air Valve in Pneumatic Shaft.

The gray type Air Inflator is used together with Horn Head Air Valve in pneumatic shaft.

1. Experiment reason

To find a better material to avoid Air leaking in Airshaft

2. Experiment Time and Staff

8th, Aug, 2020.-------8th, Jan, 2021 (Lasting for Half a year)

Factory technical manager and Quality Control Team

3. Experiment Operation

(1) 10, 000pcs copper Air valve and 10, 000 pcs Stainless steel Airvalve Valve for Air inflation to check random leaking rate

(2) Mass Air inflation test of After finishing 10,000 times air inflation and deflation for each air valve. And to see which how many air vlave is still in good using situation and NOT LEAK AIR.

(1000 pcs copper air valves and 1000 pcs Stainless steel air valves are used in this test)

4. Experiment Results

Copper Air Valve:

(1) Air leaking possibility without using====1.5%=1.5/100

(2) Air leaking situation after 10,000 times inflation and deflation==== 10%=10/100

Stainless Steel Air Valve :

(1) Air leaking possibility without using====1/3000

(2) Air leaking situation after 10,000 times inflation and deflation====0%

Additional Experience:

Copper Airshaft valve for reason of it raw material, it is more easily for broken.

Broken mean totally broken by Half, it is a situation happened in a certain case.

SS Air shaft valve can avoid this situation.

Note: The Air valve are all in good situation before Inflation and Deflation Test. They are assembled in Airshaft to simulate the real using situation.

There are a lot of type of air shaft valves in market.

If you would like to make the purchase, you can compare the dimension with our standard airshaft part.

If still there is something you not see, you can send the photo and make a simple dimension drawing to sales!

If there are still something you not see in our webstie,

Please take the photo and send to Sales!

We are confident to GET ALL THINGS you need!

Standard Dimension of the Air valves in Air shaft.

Download this link to get all types drawing of the air inflation valves.

1/4 arrow

Air shaft valve

1/8 arrow

Air shaft valve

3/8 arrow

Air shaft valve

M10x1 arrow

Air shaft valve

M12x1 arrow

Air shaft valve

M14x1 arrow 1

Air shaft valve

M14x1 arrow 2

Air shaft valve

M14x1.5 arrow

Air shaft valve

There are also some M16 Air valve, can contact sales for more information.

The air valve is a crucial component of the air expanding shaft system. Here's some information about it:

Function: The air valve is responsible for inflating or deflating the air expanding shaft, controlling its expansion and contraction. When inflated, the shaft grips the core of the roll securely, allowing for rotation and unwinding of the material. When deflated, the roll can be easily removed or replaced.

Design and Operation: The air valve is typically mounted on the air expanding shaft and connected to a source of compressed air. It features a mechanism that allows for controlled inflation and deflation of the shaft. The valve can be manually operated or automated, depending on the specific application and requirements.

Control Methods: The air valve of an air expanding shaft can be operated through various control methods, including:

(1) Manual Control: This involves using a manual valve or lever to regulate the airflow into the shaft. The operator manually adjusts the valve to inflate or deflate the shaft as needed.

(2) Pneumatic Control: In this case, the air valve is connected to a pneumatic control system that automatically regulates the airflow based on preset parameters or feedback from sensors. This allows for precise and consistent control over the expansion and contraction of the shaft.

Safety Features: Air valves in air expanding shaft systems often incorporate safety features to prevent accidental deflation of the shaft. These features can include locking mechanisms or pressure sensors that ensure the shaft remains inflated during operation.

Applications: Air expanding shafts with air valves are commonly used in industries such as printing, packaging, converting, and paper manufacturing. They provide efficient and reliable support for rolls of material, allowing for smooth unwinding or rewinding processes. So, it is very important to choose a reliable air valve during using the air shaft.

Our goal is to make customer feel satisfied about the quality and price of the Airshaft!

We welcome if you would like to have an online factory tour!

It only take 1 minute!

This is the video of Our Factory will fully equipped Airshaft Manufactuering Devices.

Using wechat and Scan this code to talk with Airshaft Sales!

Mr Terrence

Using Whatsapp and Scan this code to talk with Airshaft Sales!

Mr Terrence