STO-STW / FLO-FLW (28-35-50 or other types)

Steel

Depend on Design

10-12 Days for Normal Order, Hurry Order is Negotiable

Wooden Box / Paper Box / Paper tube / Bubble Film

By Sea / By Air / By Train / By Fedex or other Express way

ISO9000/CE/ROHS/Certificate of Origin

Technical Video Support

T/T/Credit Card/Paypal.....

| Availability: | |

|---|---|

| Quantity: | |

| PDF Export | |

The primary function of a safety chuck is to provide secure and reliable support while allowing for easy loading and unloading of the rolls. They provide rotational support, allowing for the unwinding or rewinding of the material during various processing operations.

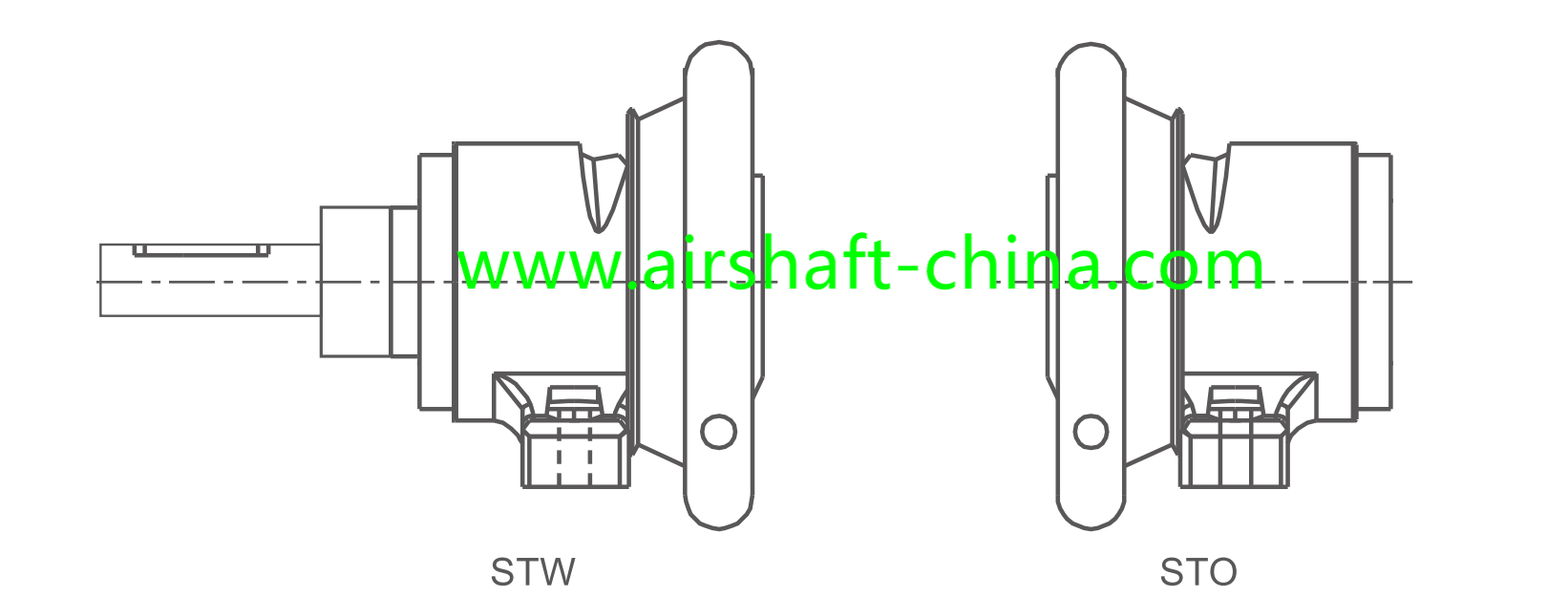

The Safety Chuck have 2 types, and following content will help readers to understand it clearly.

Each type of the Safety chuck have different dimensions,

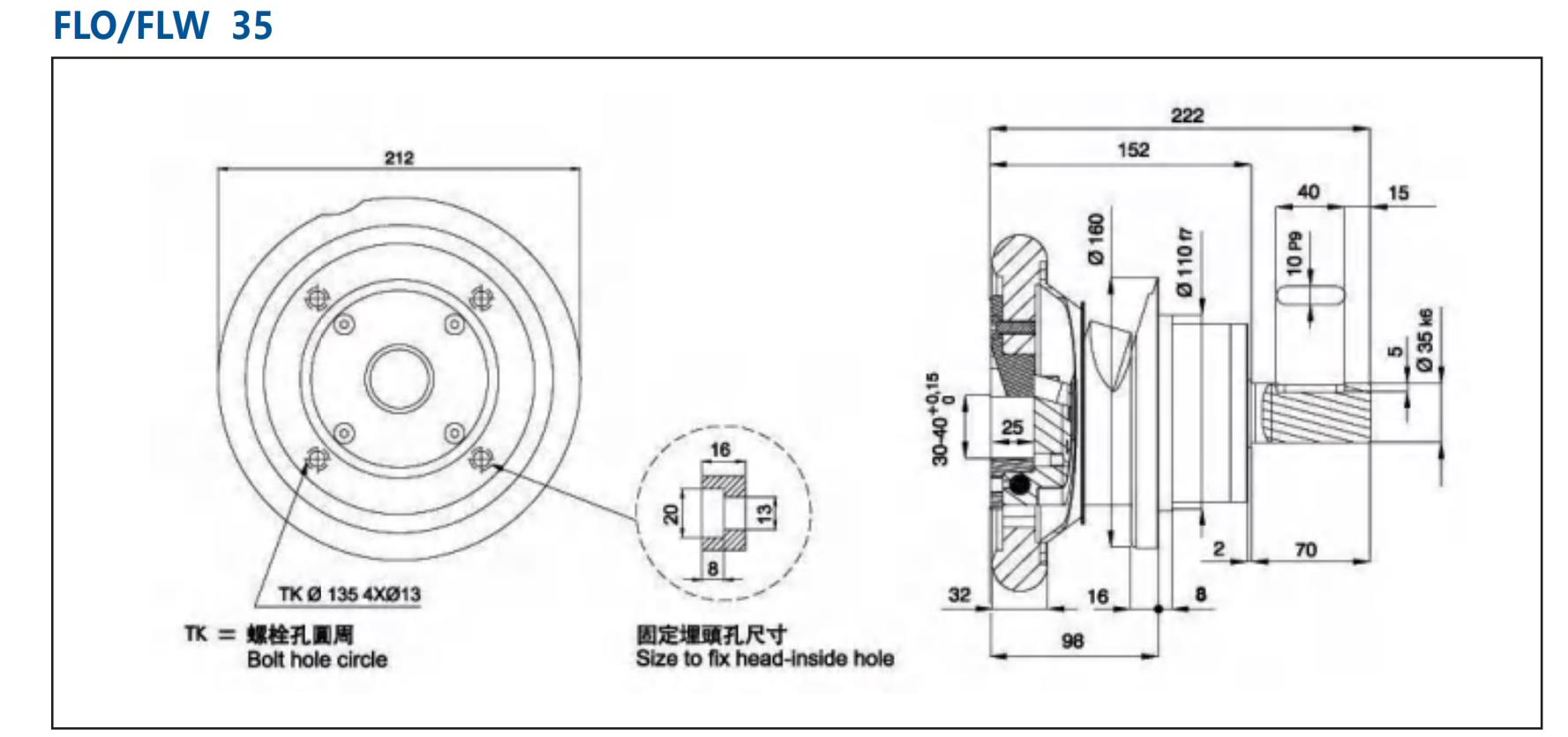

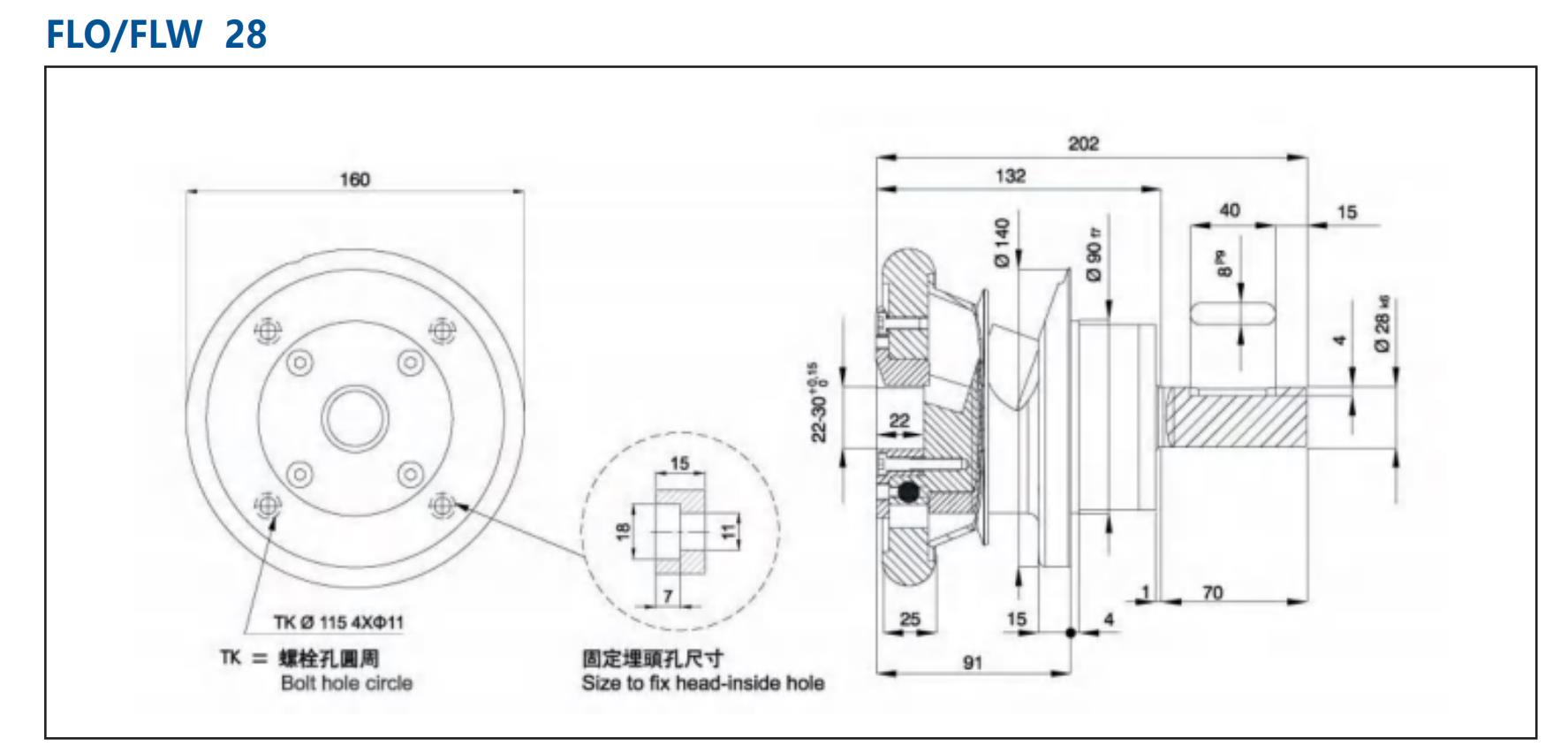

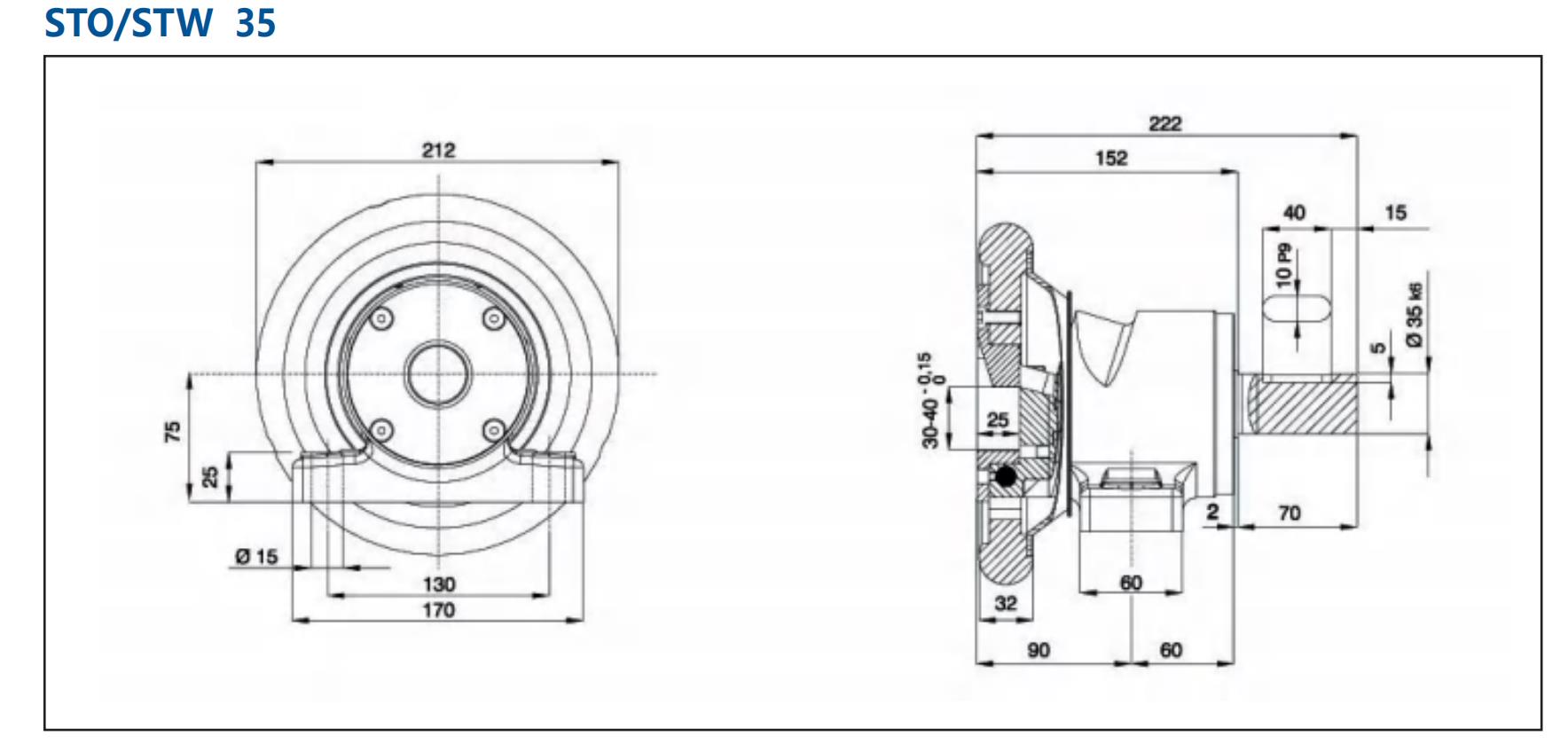

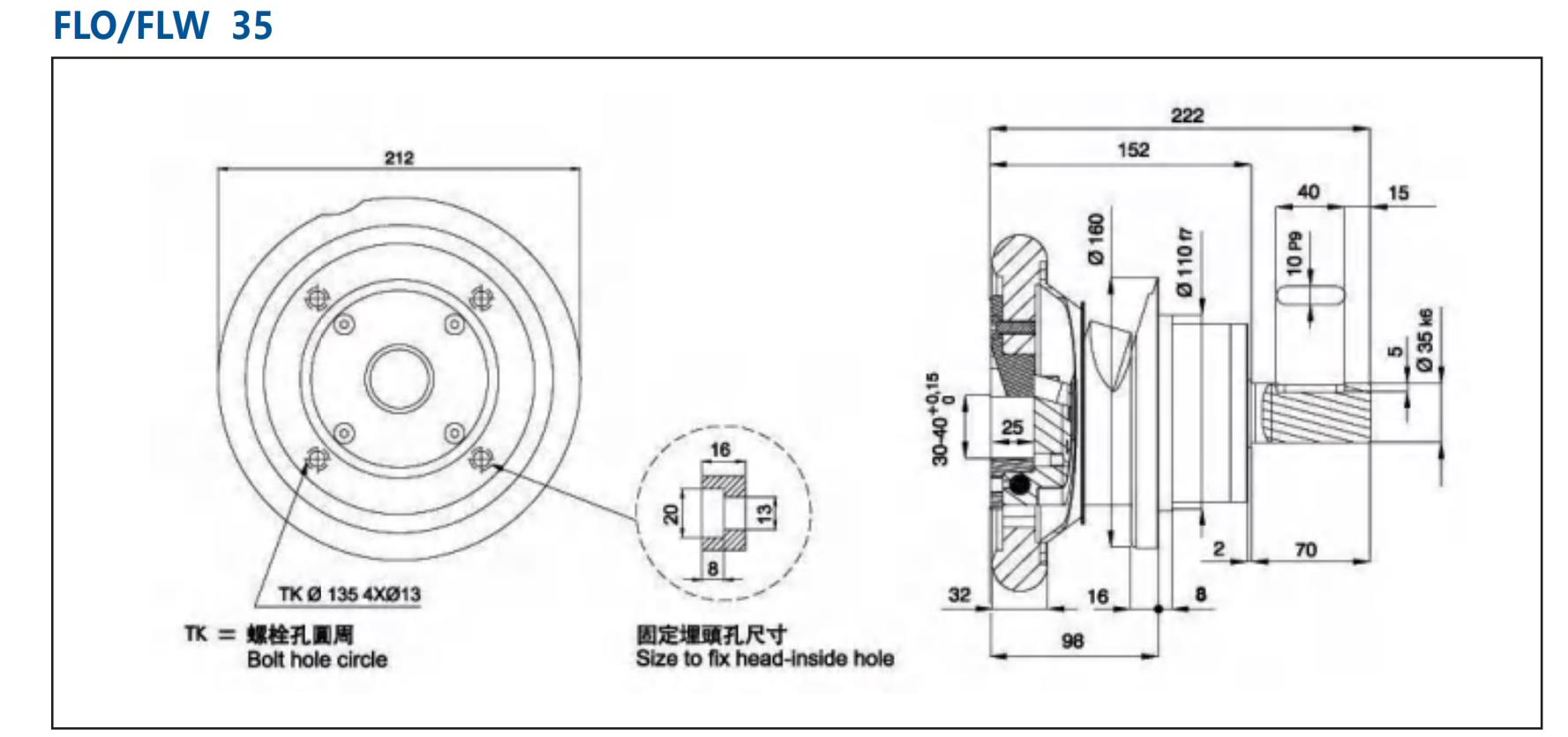

28type, 35type, 50type. You will see the drawings in the Chapter 3.

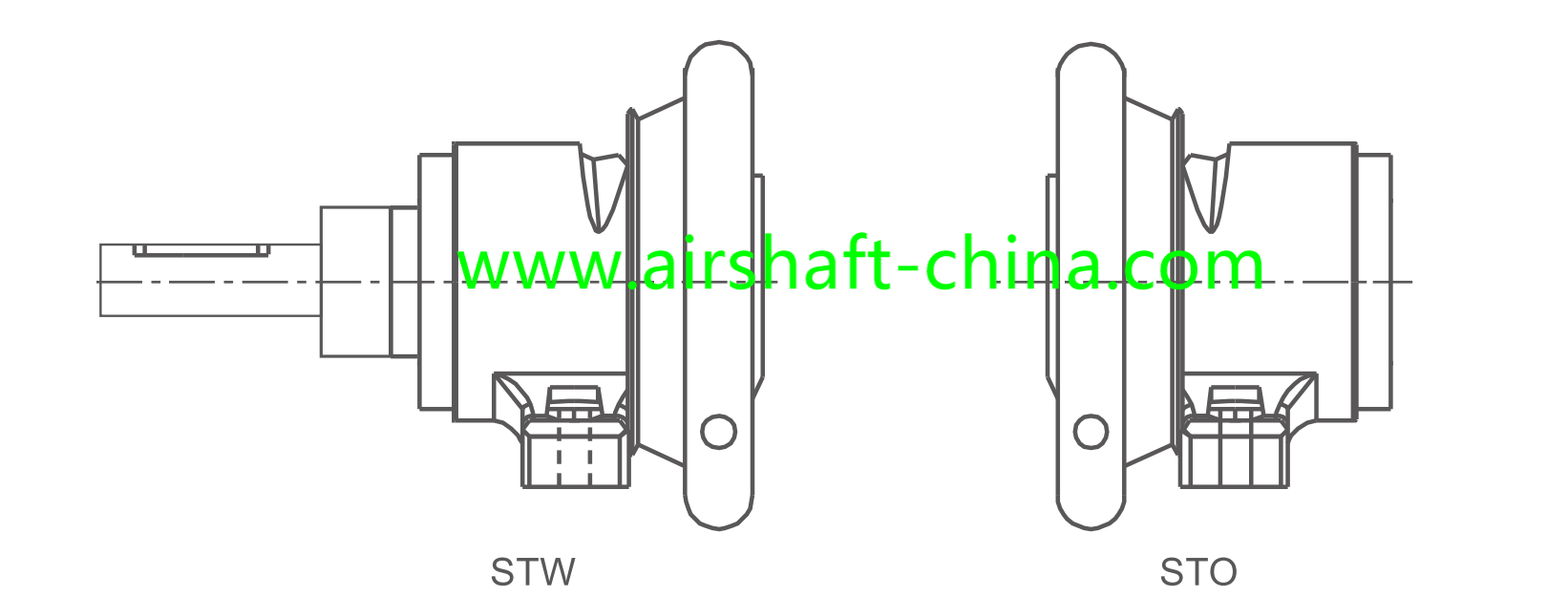

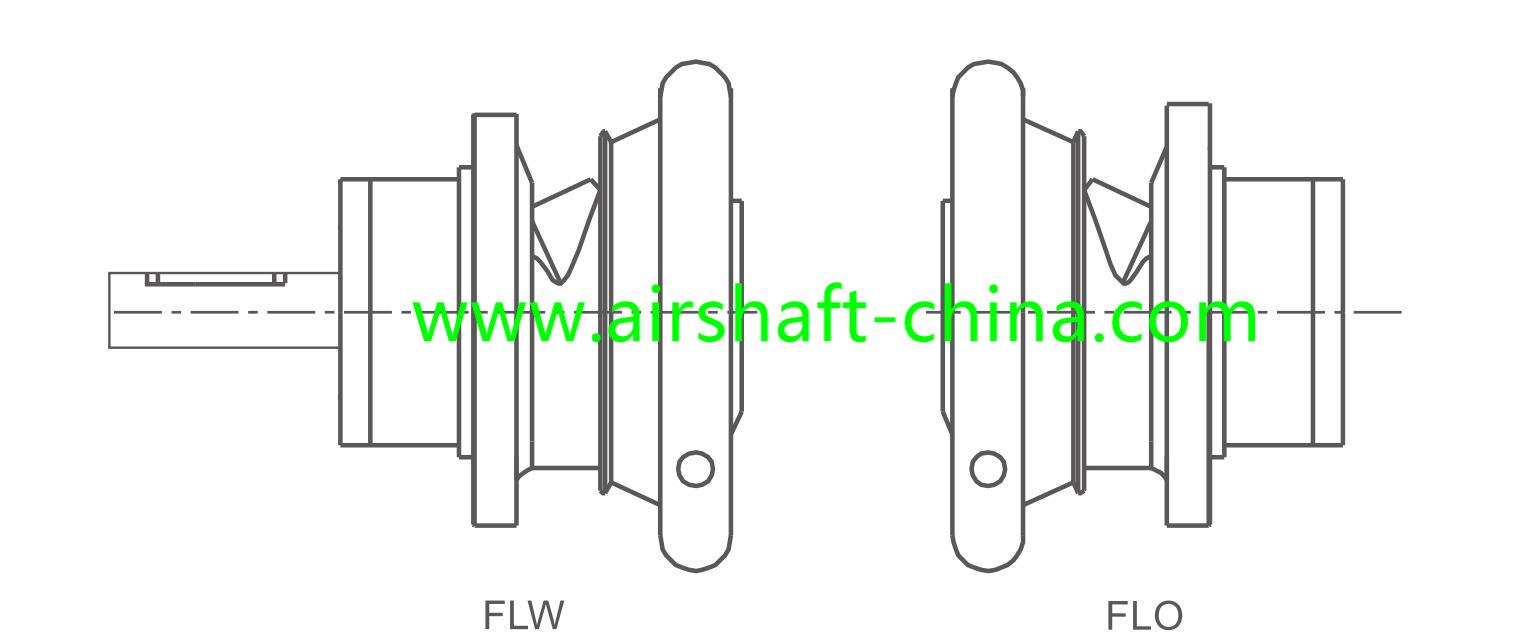

In normal case, one chuck has the shaft and another not have the transmission shaft.

The chuck halves are designed to interlock when engaged, providing a secure grip on the shaft or core. The interlocking mechanism can be actuated manually or automatically, depending on the specific design and requirements.

(1) Seated Type Safety Chuck (foot mounted)

(1) Seated Type Safety ChuckExample

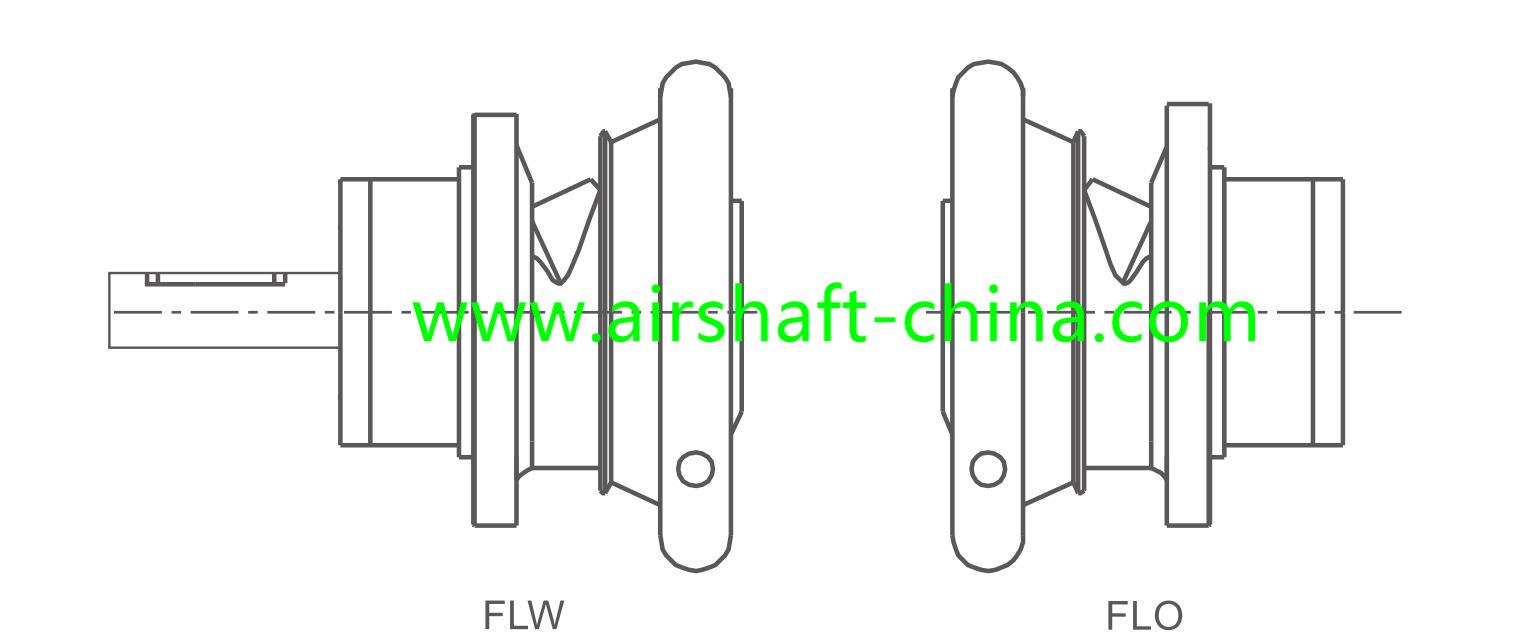

(2) FlangeType Safety Chuk

(2) FlangeType Safe Chuck Example

If you still have question of the type of your Safety Chuck, You can send the photo to Sales: TerrenceQi@outlook.com

(Note: Drawing Dimension accept Revisement or Tailor Making)

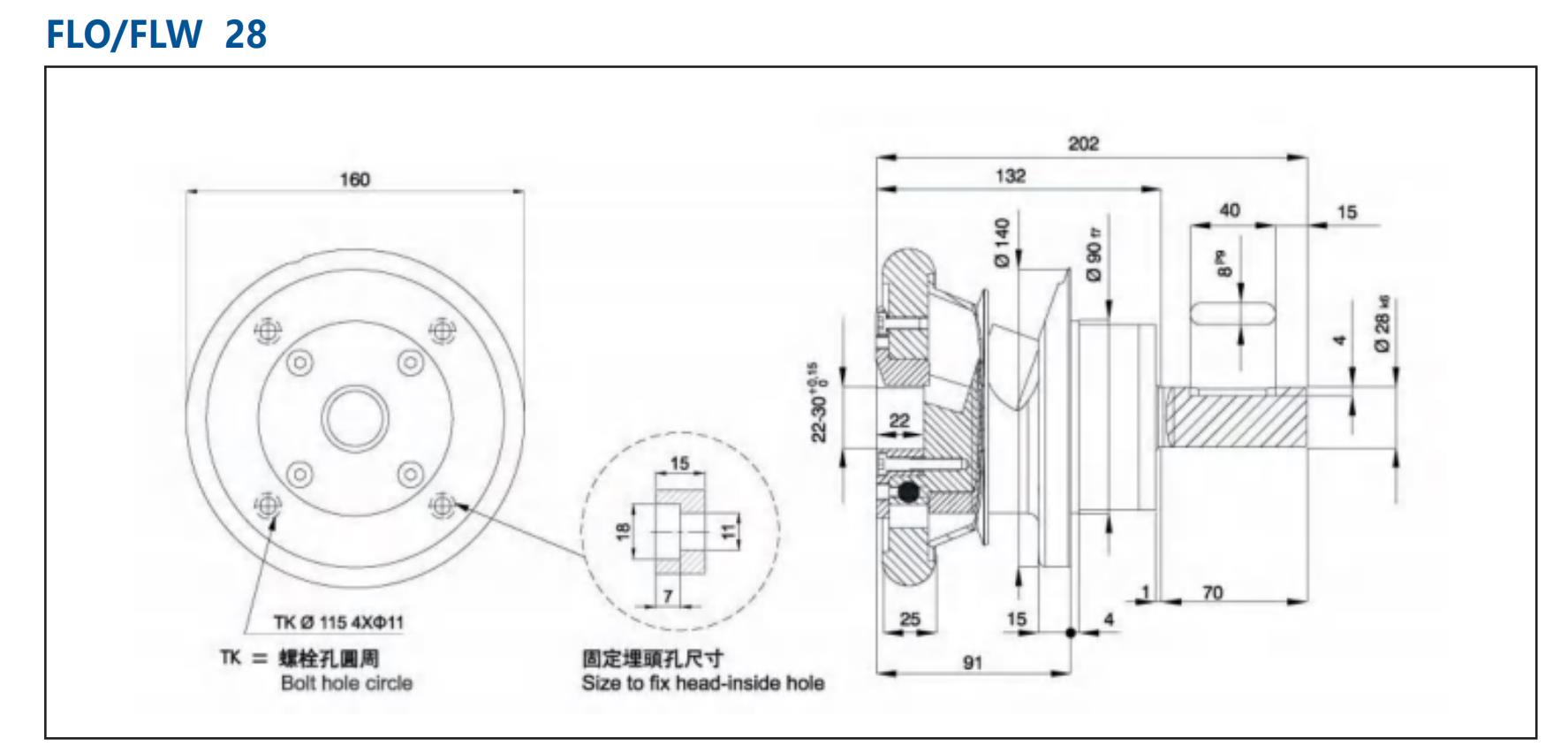

(1) 28 Type Safety Chuck

| 型号 | Model | FLO/FLW 28--Flange | STO/STW 28--Seated |

| 极限承重 | Maximum Weight Load Ability | 800kg | 800kg |

| 极限扭矩 | Maximum Torque kg/m (N/m) | 18 (180) | 18 (180) |

| 气涨轴方口尺寸 | Airshaft Square Dimension (enter inside safety chuck) | 22-30mm | 22-30mm |

| 卡盘自重 | Self Net Weight | 18kg | 18kg |

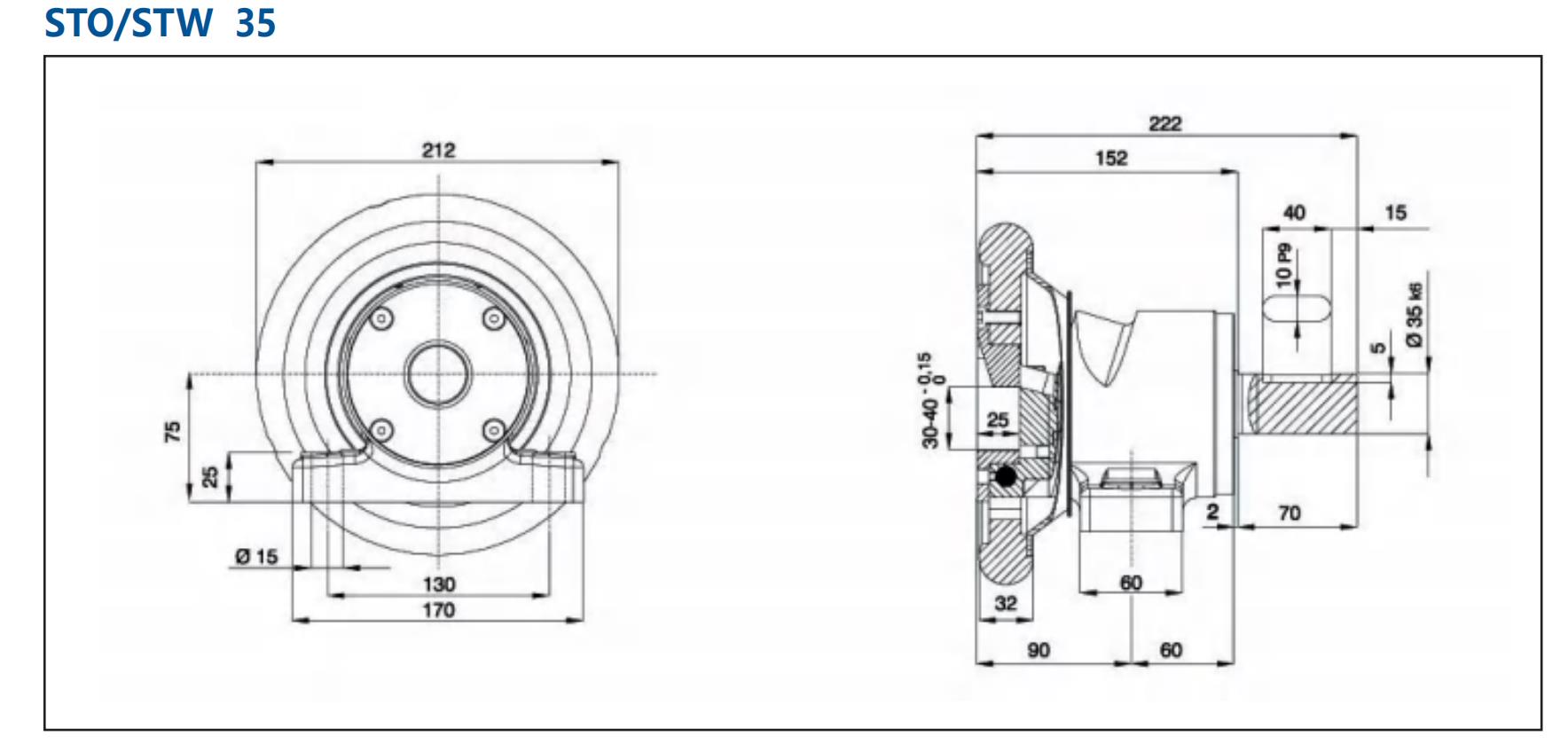

| 型号 | Model | FLO/FLW 35--Flange | STO/STW 35--Seated |

| 极限承重 | Maximum Weight Load Ability | 1600kg | 1600kg |

| 极限扭矩 | Maximum Torque kg/m (N/m) | 35 (350) | 35 (350) |

| 气涨轴方口尺寸 | Airshaft Square Dimension (enter inside safety chuck) | 30-40mm | 30-40mm |

| 卡盘自重 | Self Net Weight | 25kg | 25kg |

| 型号 | Model | FLO/FLW 50--Flange | STO/STW 50--Seated |

| 极限承重 | Maximum Weight Load Ability | 2800kg | 2800kg |

| 极限扭矩 | Maximum Torque kg/m (N/m) | 110 (1100) | 110 (1100) |

| 气涨轴方口尺寸 | Airshaft Square Dimension (enter inside safety chuck) | 40-50mm | 40-50mm |

| 卡盘自重 | Self Net Weight | 50kg | 50kg |

Incorporating safety chucks into industrial processes offers several benefits, including:

Enhanced Safety: By securely holding the core of material rolls, safety chucks minimize the risk of accidents caused by roll movement or slippage, ensuring a safer working environment.

Improved Efficiency: The stable and controlled unwinding of materials facilitated by safety chucks leads to enhanced productivity, reduced downtime, and improved overall operational efficiency.

Versatility: Safety chucks are available in various sizes and configurations, making them adaptable to different types of machinery and material handling requirements.

Easy Installation and Adjustment: Safety chucks are designed for ease of use, allowing for quick installation and adjustments to accommodate different core sizes.

Proper maintenance and care are essential for the longevity and optimal performance of safety chucks. Here are some maintenance tips:

Regular Inspection: Periodically check the condition of safety chucks, looking for any signs of wear, damage, or misalignment.

Lubrication: Apply appropriate lubricants to ensure smooth operation and prevent excessive friction.

Cleaning: Keep safety chucks clean from dust, debris, or any material residues that may affect their performance.

Adjustments: Regularly inspect and adjust the clamping force to maintain optimal gripping on the material cores.

When working with safety chucks, it is crucial to follow safety guidelines to prevent accidents and ensure a secure working environment. Some key guidelines include:

Proper Training: Ensure that operators receive adequate training on the safe operation and maintenance of safety chucks.

Wear Protective Gear: Operators should wear appropriate personal protective equipment (PPE), including gloves and safety glasses, to minimize the risk of injury.

Secure Lockout/Tagout Procedures: Implement lockout/tagout procedures to prevent accidental startup of machinery during maintenance or servicing.

Regular Inspections: Regularly inspect safety chucks for any signs of wear, damage, or malfunction and address any issues promptly.

In case of any issues with safety chucks, consider the following troubleshooting tips:

Loose Grip: If the safety chucks are not gripping the core properly, check if the clamping force requires adjustment or if there are any obstructions preventing proper contact.

Slippage: If the material is slipping during operation, ensure that the safety chucks are tightened adequately, and check for any contamination or damage on the clamping surfaces.

Uneven Tension: In cases of uneven tension in the material, verify that the safety chucks are adjusted symmetrically and that the roll is centered.

Our goal is to make customer feel satisfied about the quality and price of the Safety Chuck and Airshaft!

We welcome if you would like to have an online factory tour!

It only take 1 minute!

This is the video of Our Factory will fully equipped Airshaft and Aluminum Roller Manufactuering Devices.

Using wechat and Scan this code to talk with Airshaft Sales!

Mr Terrence

Using wechat and Scan this code to talk with Airshaft Sales!

Mr Terrence

The primary function of a safety chuck is to provide secure and reliable support while allowing for easy loading and unloading of the rolls. They provide rotational support, allowing for the unwinding or rewinding of the material during various processing operations.

The Safety Chuck have 2 types, and following content will help readers to understand it clearly.

Each type of the Safety chuck have different dimensions,

28type, 35type, 50type. You will see the drawings in the Chapter 3.

In normal case, one chuck has the shaft and another not have the transmission shaft.

The chuck halves are designed to interlock when engaged, providing a secure grip on the shaft or core. The interlocking mechanism can be actuated manually or automatically, depending on the specific design and requirements.

(1) Seated Type Safety Chuck (foot mounted)

(1) Seated Type Safety ChuckExample

(2) FlangeType Safety Chuk

(2) FlangeType Safe Chuck Example

If you still have question of the type of your Safety Chuck, You can send the photo to Sales: TerrenceQi@outlook.com

(Note: Drawing Dimension accept Revisement or Tailor Making)

(1) 28 Type Safety Chuck

| 型号 | Model | FLO/FLW 28--Flange | STO/STW 28--Seated |

| 极限承重 | Maximum Weight Load Ability | 800kg | 800kg |

| 极限扭矩 | Maximum Torque kg/m (N/m) | 18 (180) | 18 (180) |

| 气涨轴方口尺寸 | Airshaft Square Dimension (enter inside safety chuck) | 22-30mm | 22-30mm |

| 卡盘自重 | Self Net Weight | 18kg | 18kg |

| 型号 | Model | FLO/FLW 35--Flange | STO/STW 35--Seated |

| 极限承重 | Maximum Weight Load Ability | 1600kg | 1600kg |

| 极限扭矩 | Maximum Torque kg/m (N/m) | 35 (350) | 35 (350) |

| 气涨轴方口尺寸 | Airshaft Square Dimension (enter inside safety chuck) | 30-40mm | 30-40mm |

| 卡盘自重 | Self Net Weight | 25kg | 25kg |

| 型号 | Model | FLO/FLW 50--Flange | STO/STW 50--Seated |

| 极限承重 | Maximum Weight Load Ability | 2800kg | 2800kg |

| 极限扭矩 | Maximum Torque kg/m (N/m) | 110 (1100) | 110 (1100) |

| 气涨轴方口尺寸 | Airshaft Square Dimension (enter inside safety chuck) | 40-50mm | 40-50mm |

| 卡盘自重 | Self Net Weight | 50kg | 50kg |

Incorporating safety chucks into industrial processes offers several benefits, including:

Enhanced Safety: By securely holding the core of material rolls, safety chucks minimize the risk of accidents caused by roll movement or slippage, ensuring a safer working environment.

Improved Efficiency: The stable and controlled unwinding of materials facilitated by safety chucks leads to enhanced productivity, reduced downtime, and improved overall operational efficiency.

Versatility: Safety chucks are available in various sizes and configurations, making them adaptable to different types of machinery and material handling requirements.

Easy Installation and Adjustment: Safety chucks are designed for ease of use, allowing for quick installation and adjustments to accommodate different core sizes.

Proper maintenance and care are essential for the longevity and optimal performance of safety chucks. Here are some maintenance tips:

Regular Inspection: Periodically check the condition of safety chucks, looking for any signs of wear, damage, or misalignment.

Lubrication: Apply appropriate lubricants to ensure smooth operation and prevent excessive friction.

Cleaning: Keep safety chucks clean from dust, debris, or any material residues that may affect their performance.

Adjustments: Regularly inspect and adjust the clamping force to maintain optimal gripping on the material cores.

When working with safety chucks, it is crucial to follow safety guidelines to prevent accidents and ensure a secure working environment. Some key guidelines include:

Proper Training: Ensure that operators receive adequate training on the safe operation and maintenance of safety chucks.

Wear Protective Gear: Operators should wear appropriate personal protective equipment (PPE), including gloves and safety glasses, to minimize the risk of injury.

Secure Lockout/Tagout Procedures: Implement lockout/tagout procedures to prevent accidental startup of machinery during maintenance or servicing.

Regular Inspections: Regularly inspect safety chucks for any signs of wear, damage, or malfunction and address any issues promptly.

In case of any issues with safety chucks, consider the following troubleshooting tips:

Loose Grip: If the safety chucks are not gripping the core properly, check if the clamping force requires adjustment or if there are any obstructions preventing proper contact.

Slippage: If the material is slipping during operation, ensure that the safety chucks are tightened adequately, and check for any contamination or damage on the clamping surfaces.

Uneven Tension: In cases of uneven tension in the material, verify that the safety chucks are adjusted symmetrically and that the roll is centered.

Our goal is to make customer feel satisfied about the quality and price of the Safety Chuck and Airshaft!

We welcome if you would like to have an online factory tour!

It only take 1 minute!

This is the video of Our Factory will fully equipped Airshaft and Aluminum Roller Manufactuering Devices.

Using wechat and Scan this code to talk with Airshaft Sales!

Mr Terrence

Using wechat and Scan this code to talk with Airshaft Sales!

Mr Terrence