According to the dimension and photo provided by customer

Steel

Depend on Design

10-18 Days for Normal Order, Hurry Order is Negotiable

Wooden Box / Paper Box / Paper tube / Bubble Film

By Sea / By Air / By Train / By Fedex or other Express way

ISO9000/CE/ROHS/Certificate of Origin

Technical Video Support

T/T/Credit Card/Paypal.....

| Availability: | |

|---|---|

| Quantity: | |

| PDF Export | |

Normally, the Friction Ring is made by steel. Some parts can be made by aluminum or Nylon/Plastic to help reduce the weight of the Friction Airshaft.

Sometimes, some customers would like to add a bearing inside the Friction ring, and we have no problem for every different design requirement of the Friction Ring.

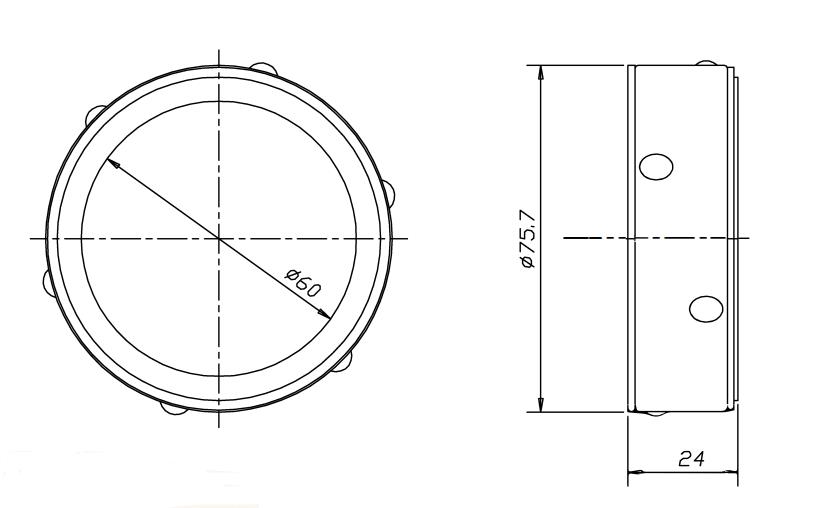

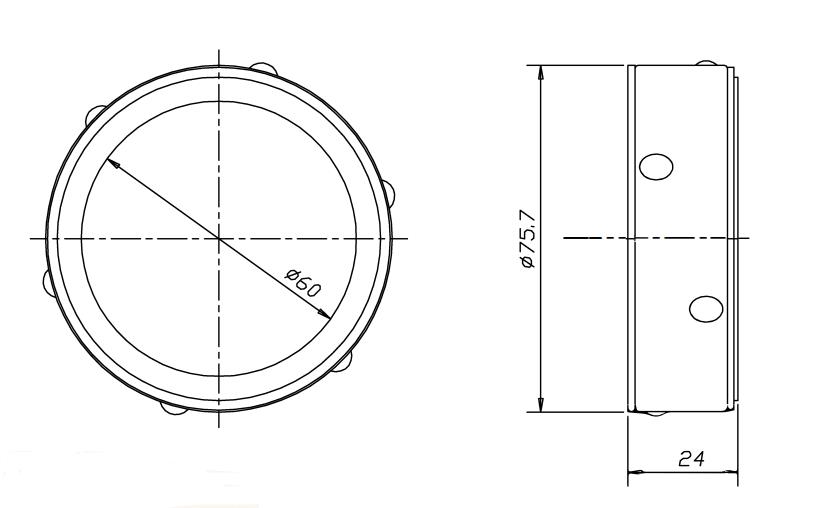

The following information is our different Friction Ring dimension example.

The Outside diameter of the Friction Ring is ok for different tailor making, normal more used type is 75mm, 120mm and 160mm.

The Width of the Friction Ring is also ok for different design

| 10mm | 25mm | 30mm | 35mm | 40mm | 50mm | More.... |

The Inner diameter of the Friction Ring

Normal is 60mm or 50mm, others accept tailor making.

Drawing Example of the Friction Ring

Friction rings are an important component of friction airshafts, also known as expanding shafts or differential shafts. The function of the friction ring is to provide a controlled amount of friction or grip on the material being wound onto or unwound from the shaft. Here's how it works:

1. Shaft Construction: A friction airshaft consists of a hollow, cylindrical core that is typically made of steel or aluminum. It has a series of internal expandable elements, usually made of rubber or similar materials, that can be inflated or deflated with air pressure.

2. Friction Ring Placement: The friction ring is positioned on the outer surface of the shaft, usually near the ends. It can be made of rubber, silicone, or other materials with high friction properties.

3. Material Gripping: When the air pressure inside the shaft's expandable elements is increased, the elements expand and push against the friction ring. The friction ring, in turn, applies a controlled amount of friction or grip to the material being wound onto the shaft.

4. Tension Control: The friction generated by the friction ring helps to maintain tension on the material during winding or unwinding processes. This controlled tension prevents material slippage, wrinkling, or loose winding, ensuring proper alignment and stability.

5. Adjustability: The level of friction provided by the friction ring can be adjusted by modifying the air pressure inside the expandable elements of the shaft. Higher air pressure increases the gripping force, while lower pressure reduces it. This adjustability allows for precise control over the tension applied to different types of materials.

Overall, the friction ring on a friction airshaft plays a vital role in maintaining tension and preventing material slippage during winding or unwinding operations. Its function is to provide controlled friction to ensure efficient and secure handling of various types of materials on the shaft.

Performing regular maintenance on the friction ring of a friction airshaft can help ensure its optimal performance and longevity. Here are some general steps you can follow for maintaining the friction ring:

1. Cleaning: Start by cleaning the friction ring to remove any dirt, debris, or accumulated residues that may affect its friction properties. You can use a soft cloth or brush along with a mild cleaning solution suitable for the material of the friction ring. Avoid using harsh chemicals or abrasive cleaners that can damage the ring's surface.

2. Inspection: Thoroughly inspect the friction ring for any signs of wear, cracks, tears, or deformities. Pay attention to the edges, where the friction ring comes into contact with the material being wound or unwound. If you notice any significant damage or deterioration, consider replacing the friction ring.

3. Lubrication (if applicable): Some friction rings may require lubrication to maintain their friction properties. Check the manufacturer's recommendations or documentation to determine if lubrication is necessary. If lubrication is recommended, use a suitable lubricant as specified by the manufacturer. Apply the lubricant sparingly and evenly on the friction ring's surface, ensuring it doesn't come into contact with the material being handled.

4. Air Pressure Check: Verify that the air pressure used to inflate the expandable elements of the friction airshaft is within the recommended range. Incorrect air pressure can affect the performance of the friction ring. Consult the airshaft's operating manual or contact the manufacturer for the appropriate air pressure guidelines.

5. Adjustments: If you find that the friction ring is not providing the desired level of grip or tension, you may need to make adjustments. This typically involves modifying the air pressure inside the expandable elements of the airshaft to increase or decrease the friction force. Follow the instructions provided by the manufacturer for adjusting the air pressure and ensure that the adjustments are made gradually and carefully.

6. Regular Inspections: Make it a routine to inspect the friction ring periodically, especially if the friction airshaft is used frequently or under demanding conditions. Regular inspections can help identify any developing issues early on, allowing for timely maintenance or replacement if necessary.

Remember to consult the specific maintenance guidelines provided by the manufacturer of your friction airshaft and follow any recommended procedures or precautions they provide.

When working with a friction ring on a friction airshaft, there are a few additional points to note:

1. Material Compatibility: Ensure that the friction ring is suitable for the specific materials you will be handling. Different materials may require different friction properties or have specific requirements that need to be considered. Consult the manufacturer's recommendations or guidelines to verify material compatibility.

2. Proper Installation: Follow the manufacturer's instructions for correctly installing the friction ring on the friction airshaft. Improper installation can lead to suboptimal performance or premature wear of the friction ring. Pay attention to the orientation and alignment of the friction ring to ensure it functions properly.

3. Avoid Excessive Force: Do not apply excessive force or overload the friction ring beyond its recommended capacity. This can cause accelerated wear, deformation, or damage to the friction ring. Adhere to the weight and load capacity limits specified by the manufacturer.

4. Storage and Handling: When the friction airshaft is not in use, store it in a clean and dry environment to prevent contamination or damage to the friction ring. Handle the friction airshaft with care, avoiding impacts or rough handling that could impact the integrity of the friction ring.

5. Regular Inspections: Along with the maintenance steps mentioned earlier, conduct regular inspections of the entire friction airshaft system, including the friction ring, airshaft core, and expandable elements. Look for any signs of wear, damage, or malfunction and address them promptly to ensure optimal performance and safety.

6. Manufacturer's Guidelines: Always refer to the manufacturer's guidelines, recommendations, and specifications for the friction airshaft and the friction ring. They are the best source of information for operating, maintaining, and troubleshooting your specific equipment.

By paying attention to these additional considerations, you can ensure that the friction ring performs effectively and contributes to the smooth operation of your friction airshaft system.

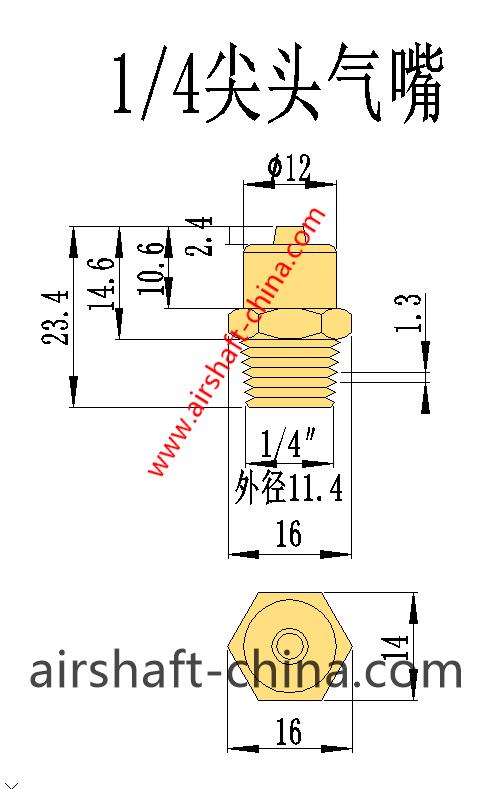

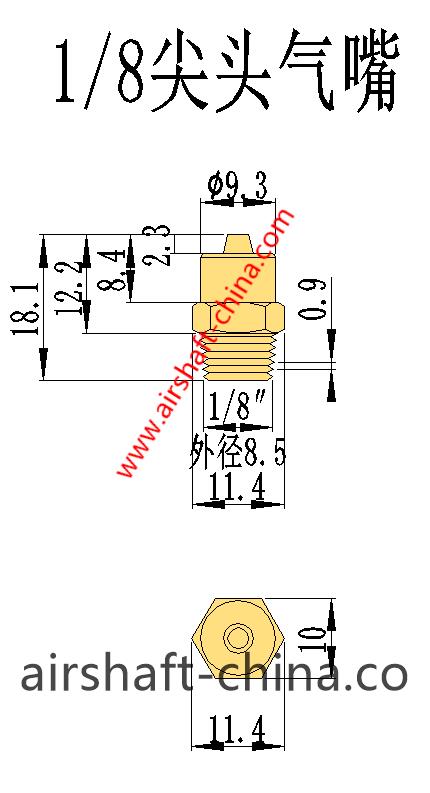

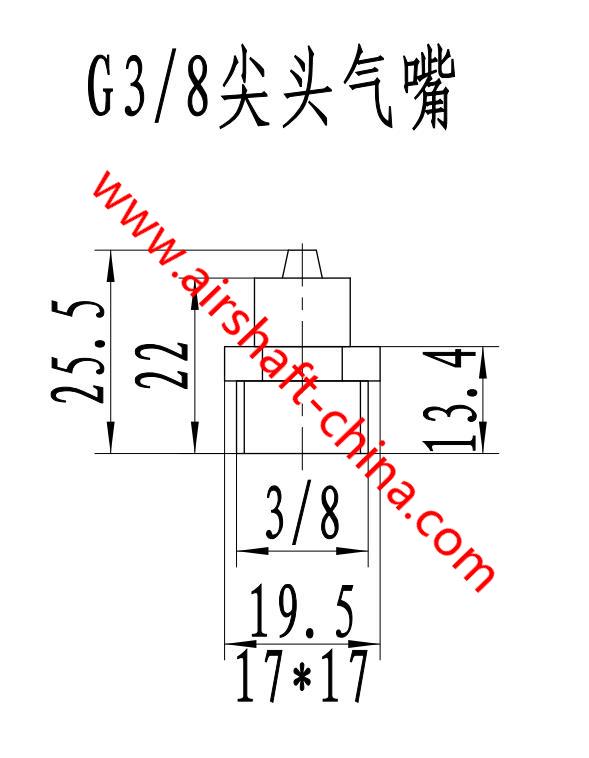

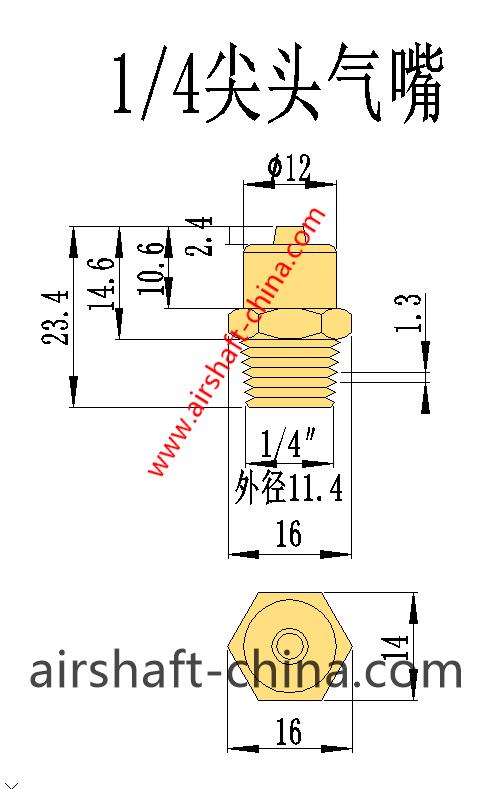

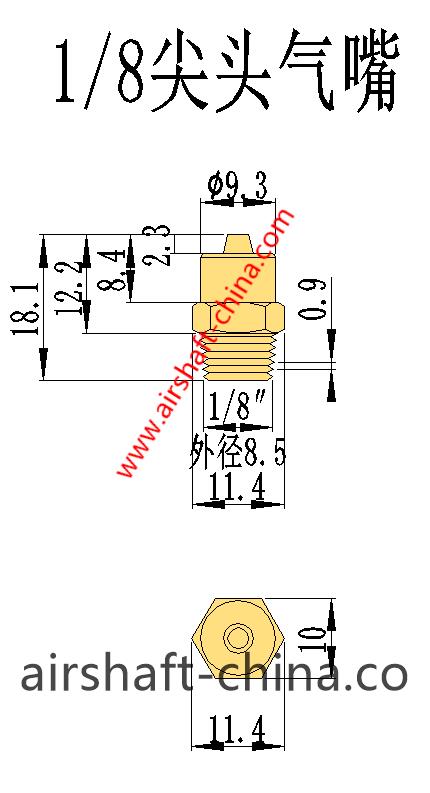

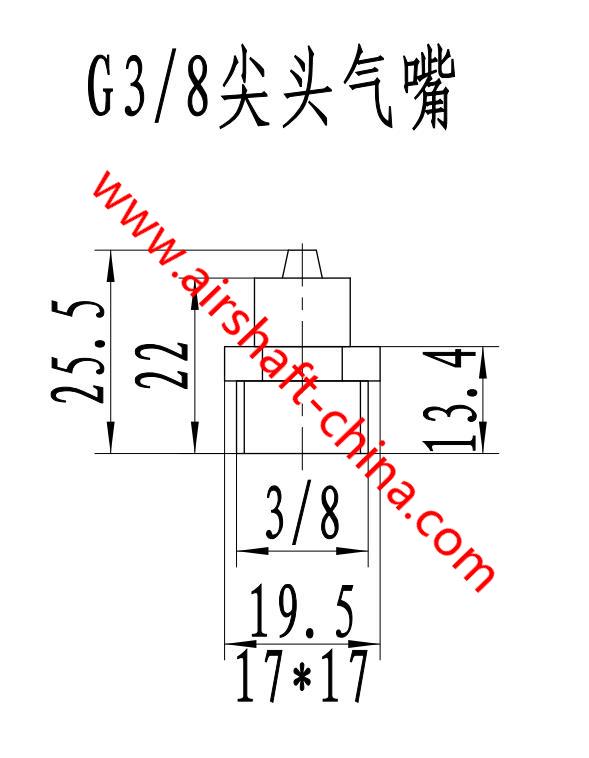

There are a lot of type of air shaft valves in market.

If you would like to make the purchase, you can compare the dimension with our standard airshaft part.

If still there is something you not see, you can send the photo and make a simple dimension drawing to sales!

If there are still something you not see in our webstie,

Please take the photo and send to Sales!

We are confident to GET ALL THINGS you need!

Standard Dimension of the Air valves in Air shaft. (only part)

Contact Sales to get the Full Set Complete Drawing!

1/4 arrow

Air shaft valve

1/8 arrow

Air shaft valve

3/8 arrow

Air shaft valve

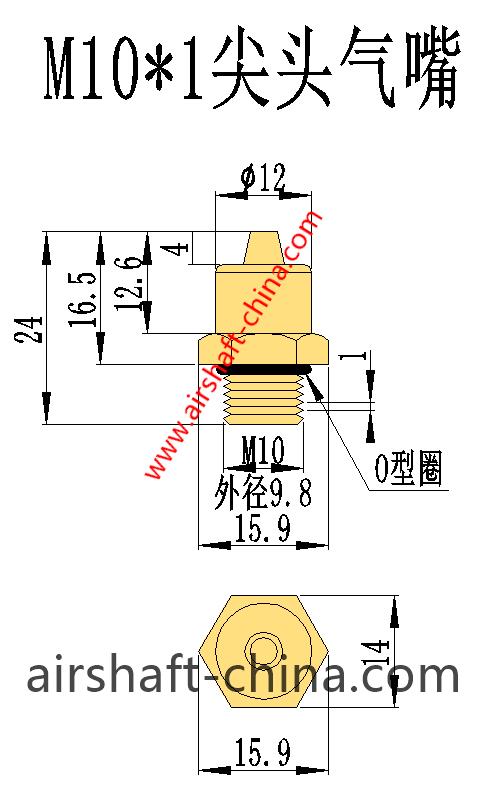

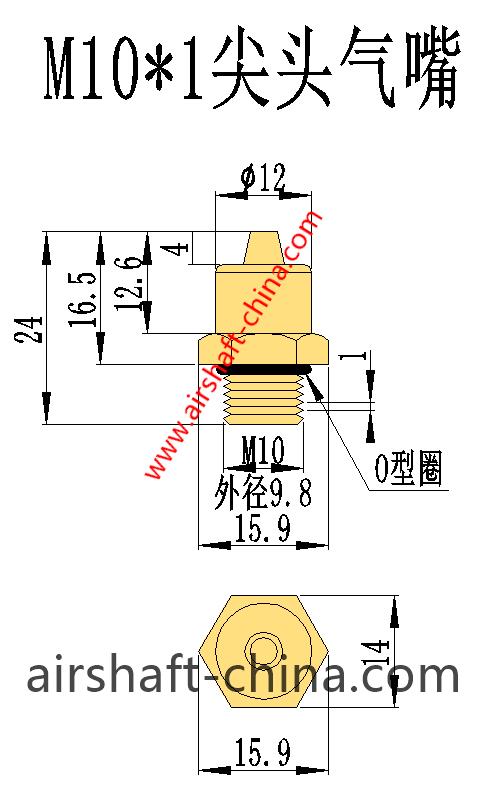

M10x1 arrow

Air shaft valve

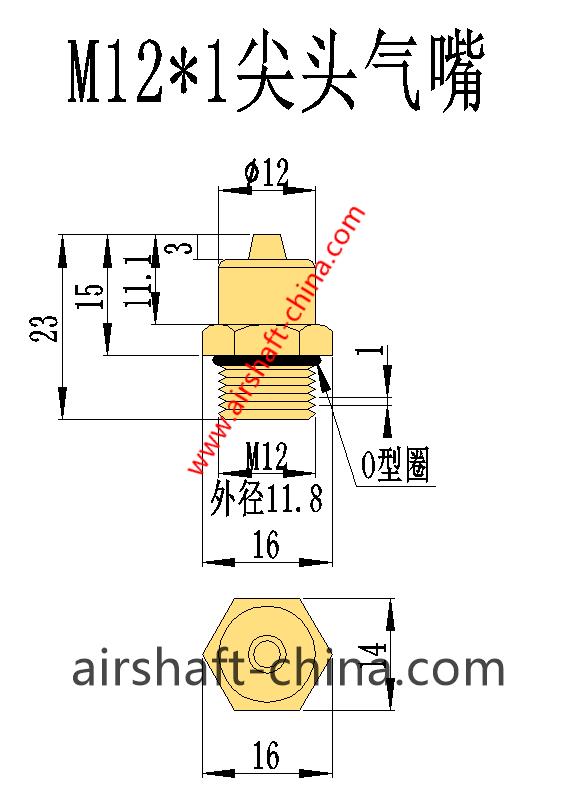

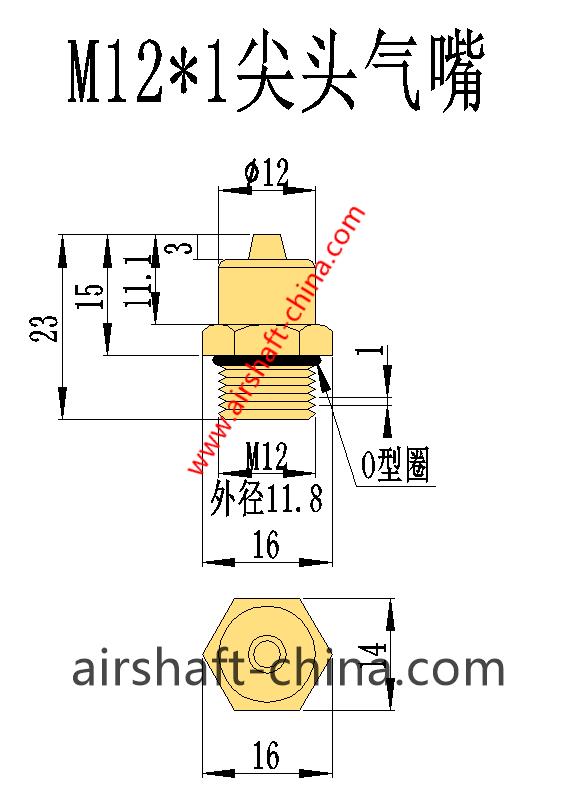

M12x1 arrow

Air shaft valve

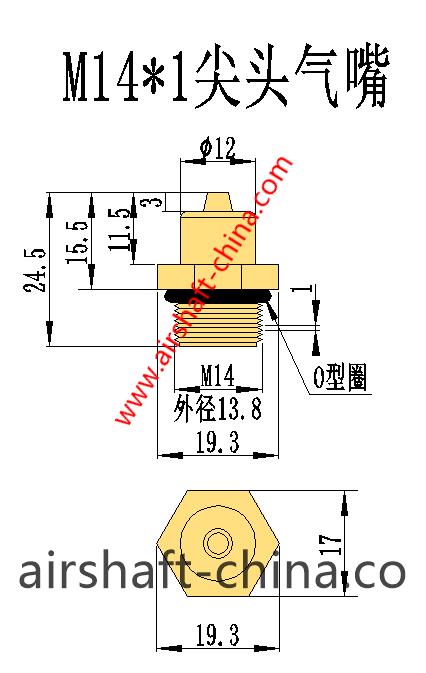

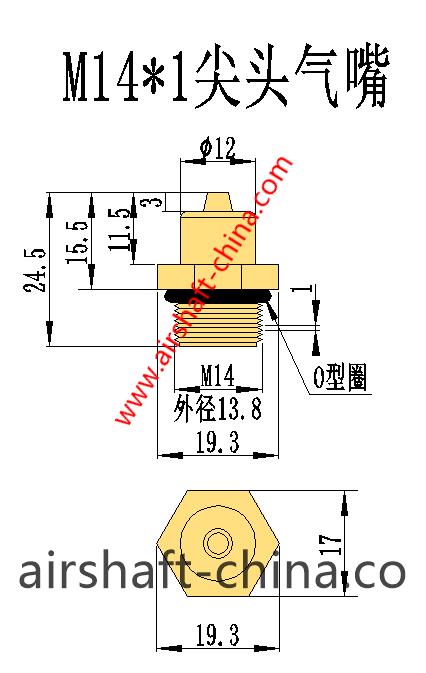

M14x1 arrow 1

Air shaft valve

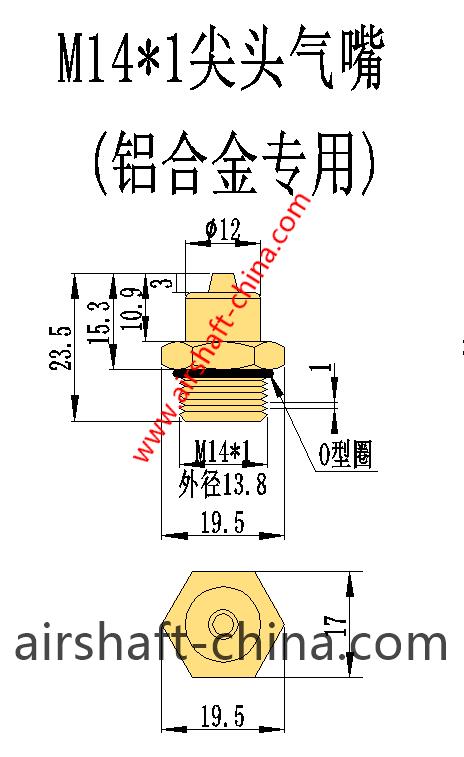

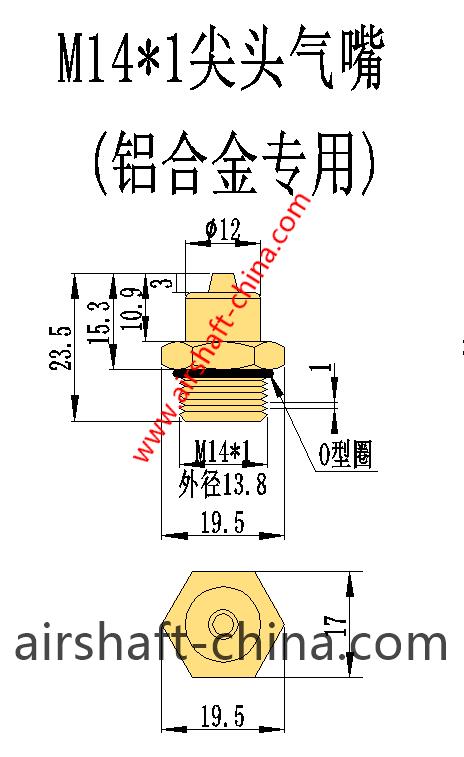

M14x1 arrow 2

Air shaft valve

M14x1.5 arrow

Air shaft valve

There are also some M16 Air valve, can contact sales for more information.

Our goal is to make customer feel satisfied about the quality and price of the Airshaft!

We welcome if you would like to have an online factory tour!

It only take 1 minute!

This is the video of Our Factory will fully equipped Airshaft Manufactuering Devices.

Using wechat and Scan this code to talk with Airshaft Sales!

Mr Terrence

Using Whatsapp and Scan this code to talk with Airshaft Sales!

Mr Terrence

Normally, the Friction Ring is made by steel. Some parts can be made by aluminum or Nylon/Plastic to help reduce the weight of the Friction Airshaft.

Sometimes, some customers would like to add a bearing inside the Friction ring, and we have no problem for every different design requirement of the Friction Ring.

The following information is our different Friction Ring dimension example.

The Outside diameter of the Friction Ring is ok for different tailor making, normal more used type is 75mm, 120mm and 160mm.

The Width of the Friction Ring is also ok for different design

| 10mm | 25mm | 30mm | 35mm | 40mm | 50mm | More.... |

The Inner diameter of the Friction Ring

Normal is 60mm or 50mm, others accept tailor making.

Drawing Example of the Friction Ring

Friction rings are an important component of friction airshafts, also known as expanding shafts or differential shafts. The function of the friction ring is to provide a controlled amount of friction or grip on the material being wound onto or unwound from the shaft. Here's how it works:

1. Shaft Construction: A friction airshaft consists of a hollow, cylindrical core that is typically made of steel or aluminum. It has a series of internal expandable elements, usually made of rubber or similar materials, that can be inflated or deflated with air pressure.

2. Friction Ring Placement: The friction ring is positioned on the outer surface of the shaft, usually near the ends. It can be made of rubber, silicone, or other materials with high friction properties.

3. Material Gripping: When the air pressure inside the shaft's expandable elements is increased, the elements expand and push against the friction ring. The friction ring, in turn, applies a controlled amount of friction or grip to the material being wound onto the shaft.

4. Tension Control: The friction generated by the friction ring helps to maintain tension on the material during winding or unwinding processes. This controlled tension prevents material slippage, wrinkling, or loose winding, ensuring proper alignment and stability.

5. Adjustability: The level of friction provided by the friction ring can be adjusted by modifying the air pressure inside the expandable elements of the shaft. Higher air pressure increases the gripping force, while lower pressure reduces it. This adjustability allows for precise control over the tension applied to different types of materials.

Overall, the friction ring on a friction airshaft plays a vital role in maintaining tension and preventing material slippage during winding or unwinding operations. Its function is to provide controlled friction to ensure efficient and secure handling of various types of materials on the shaft.

Performing regular maintenance on the friction ring of a friction airshaft can help ensure its optimal performance and longevity. Here are some general steps you can follow for maintaining the friction ring:

1. Cleaning: Start by cleaning the friction ring to remove any dirt, debris, or accumulated residues that may affect its friction properties. You can use a soft cloth or brush along with a mild cleaning solution suitable for the material of the friction ring. Avoid using harsh chemicals or abrasive cleaners that can damage the ring's surface.

2. Inspection: Thoroughly inspect the friction ring for any signs of wear, cracks, tears, or deformities. Pay attention to the edges, where the friction ring comes into contact with the material being wound or unwound. If you notice any significant damage or deterioration, consider replacing the friction ring.

3. Lubrication (if applicable): Some friction rings may require lubrication to maintain their friction properties. Check the manufacturer's recommendations or documentation to determine if lubrication is necessary. If lubrication is recommended, use a suitable lubricant as specified by the manufacturer. Apply the lubricant sparingly and evenly on the friction ring's surface, ensuring it doesn't come into contact with the material being handled.

4. Air Pressure Check: Verify that the air pressure used to inflate the expandable elements of the friction airshaft is within the recommended range. Incorrect air pressure can affect the performance of the friction ring. Consult the airshaft's operating manual or contact the manufacturer for the appropriate air pressure guidelines.

5. Adjustments: If you find that the friction ring is not providing the desired level of grip or tension, you may need to make adjustments. This typically involves modifying the air pressure inside the expandable elements of the airshaft to increase or decrease the friction force. Follow the instructions provided by the manufacturer for adjusting the air pressure and ensure that the adjustments are made gradually and carefully.

6. Regular Inspections: Make it a routine to inspect the friction ring periodically, especially if the friction airshaft is used frequently or under demanding conditions. Regular inspections can help identify any developing issues early on, allowing for timely maintenance or replacement if necessary.

Remember to consult the specific maintenance guidelines provided by the manufacturer of your friction airshaft and follow any recommended procedures or precautions they provide.

When working with a friction ring on a friction airshaft, there are a few additional points to note:

1. Material Compatibility: Ensure that the friction ring is suitable for the specific materials you will be handling. Different materials may require different friction properties or have specific requirements that need to be considered. Consult the manufacturer's recommendations or guidelines to verify material compatibility.

2. Proper Installation: Follow the manufacturer's instructions for correctly installing the friction ring on the friction airshaft. Improper installation can lead to suboptimal performance or premature wear of the friction ring. Pay attention to the orientation and alignment of the friction ring to ensure it functions properly.

3. Avoid Excessive Force: Do not apply excessive force or overload the friction ring beyond its recommended capacity. This can cause accelerated wear, deformation, or damage to the friction ring. Adhere to the weight and load capacity limits specified by the manufacturer.

4. Storage and Handling: When the friction airshaft is not in use, store it in a clean and dry environment to prevent contamination or damage to the friction ring. Handle the friction airshaft with care, avoiding impacts or rough handling that could impact the integrity of the friction ring.

5. Regular Inspections: Along with the maintenance steps mentioned earlier, conduct regular inspections of the entire friction airshaft system, including the friction ring, airshaft core, and expandable elements. Look for any signs of wear, damage, or malfunction and address them promptly to ensure optimal performance and safety.

6. Manufacturer's Guidelines: Always refer to the manufacturer's guidelines, recommendations, and specifications for the friction airshaft and the friction ring. They are the best source of information for operating, maintaining, and troubleshooting your specific equipment.

By paying attention to these additional considerations, you can ensure that the friction ring performs effectively and contributes to the smooth operation of your friction airshaft system.

There are a lot of type of air shaft valves in market.

If you would like to make the purchase, you can compare the dimension with our standard airshaft part.

If still there is something you not see, you can send the photo and make a simple dimension drawing to sales!

If there are still something you not see in our webstie,

Please take the photo and send to Sales!

We are confident to GET ALL THINGS you need!

Standard Dimension of the Air valves in Air shaft. (only part)

Contact Sales to get the Full Set Complete Drawing!

1/4 arrow

Air shaft valve

1/8 arrow

Air shaft valve

3/8 arrow

Air shaft valve

M10x1 arrow

Air shaft valve

M12x1 arrow

Air shaft valve

M14x1 arrow 1

Air shaft valve

M14x1 arrow 2

Air shaft valve

M14x1.5 arrow

Air shaft valve

There are also some M16 Air valve, can contact sales for more information.

Our goal is to make customer feel satisfied about the quality and price of the Airshaft!

We welcome if you would like to have an online factory tour!

It only take 1 minute!

This is the video of Our Factory will fully equipped Airshaft Manufactuering Devices.

Using wechat and Scan this code to talk with Airshaft Sales!

Mr Terrence

Using Whatsapp and Scan this code to talk with Airshaft Sales!

Mr Terrence